Insight Focus

- Domestic sugar prices have weakened.

- The ban on B-molasses means processors must use C-molasses to produce ethanol.

- Mills pressuring the government for support with revenue generation.

Introduction

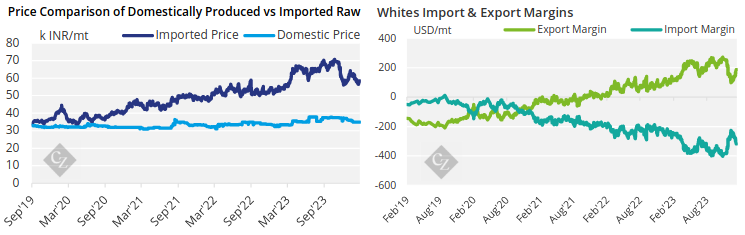

India, the world’s second-largest producer of sugar, aims to blend 20% ethanol in gasoline by 2025.

This ethanol will be made from sugar cane and various grain feedstocks, which means many Indian mills now have a choice about how they use the sucrose in the cane. We will show the choices they are making in this report.

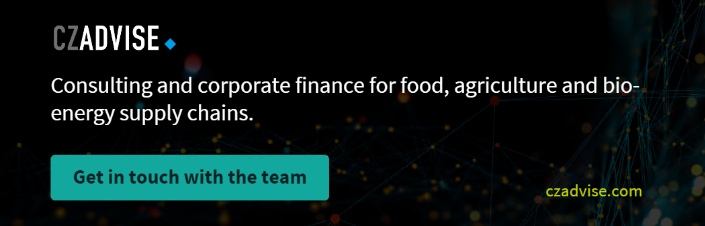

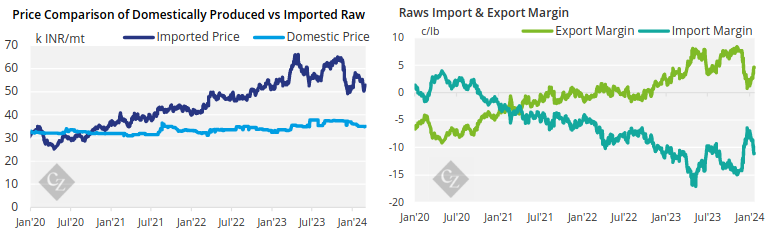

Maharashtra Sugar Imports/Exports

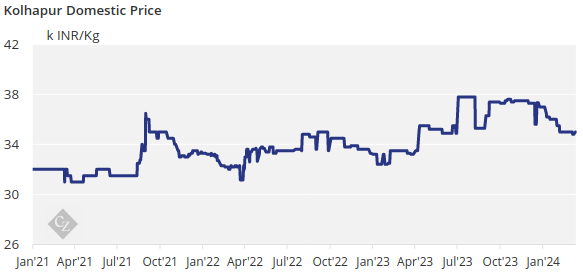

Since our last report, domestic sugar prices have weakened to 35k INR/kg.

With the elections coming up in April, the Indian government has prioritised the country’s food security concerns. To address this, the government has decided to cap sugar diversion to ethanol at 1.7m tonnes.

Although imports are not required at this time, mills are unable to capitalise on large margins because of the export ban on sugar, as there is still an insufficient amount of sugar to allow for an export quota to be released.

Ethanol vs Sugar

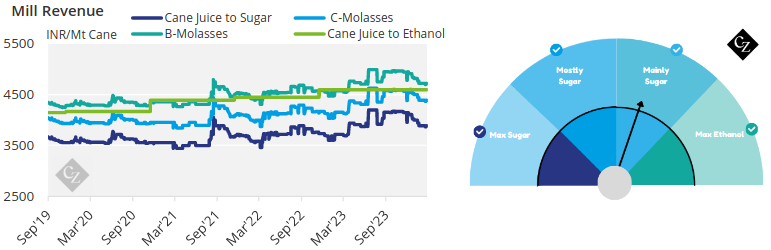

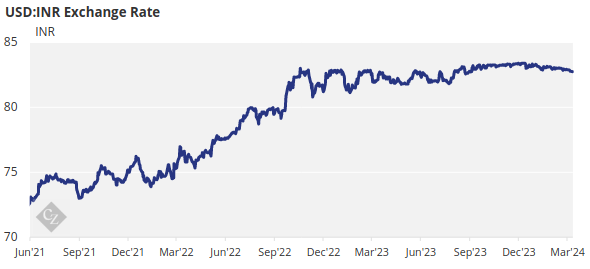

Many mills/distilleries have a choice over which feedstocks they use to make sugar or ethanol based on the relative prices of ethanol paid by the oil marketing companies.

In previous reports we have hinted that the government could incentivise mills to use C-molasses for sugar production, reducing the ethanol diversion.

The Indian government has restricted ethanol production from B-molasses and cane juice. Processors will now have to use C-molasses to make ethanol. The amount of sugar produced from C-molasses vastly outweighs ethanol production compared to using B-molasses and cane juice, resulting in less revenue generated by the mills as seen in the chart below:

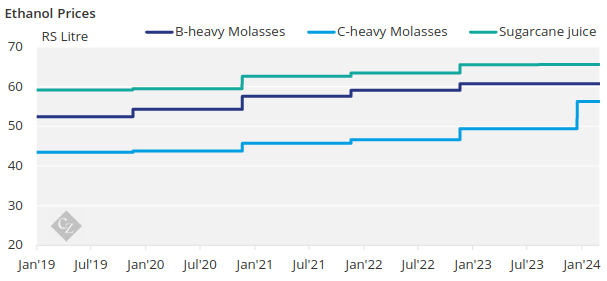

Here are the current prices paid for ethanol by feedstock:

Appendix

If you have any questions, please get in touch with us at Jack@czapp.com.