Insight Focus

Sustainable aviation fuel (SAF) is the only realistic route for net carbon emissions to be reduced for air travel. However, the challenge for producers is now to upgrade the energy content of SAF feedstocks so they can compete with traditional alternatives.

Combustion Abatement Required So far, we’ve had a look at a glossary of terms used in the world of SAF, how it’s made and how specification authorities control the process of introducing SAF into the jet fuel pool, and so help keep the flying public safe.

As we saw, SAF means both synthetic aviation fuel and sustainable aviation fuel, which may seem confusing. But what is clear is that SAF has different levels of sustainability. What do we mean by this?

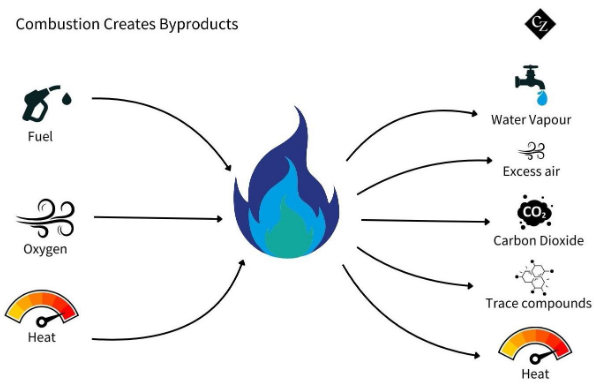

When an aircraft flies through the air, the engines are combusting jet fuel in the presence of oxygen from the air from the atmosphere. The conversion of the fuel to exhaust gases (combustion) produces carbon dioxide (what chemists call CO2).

There are other products, including water (H2O), sulphur di- and tri-oxides (SOx), nitrogen oxides (NOx) and other combustion biproducts, but the marker for environmental impact is carbon dioxide, often abbreviated to just ‘carbon’.

So, the combustion of jet fuel to carbon dioxide is the key process that the industry absolutely depends on for mobility and yet is trying to abate.

How Can Abatement Happen?

There are three principal pathways.

1. Efficiency Improvement

First, we improve efficiency and so produce less CO2 for each passenger-kilometre flown. This can be done through improved aircraft design, including the use of better, lighter materials. We could also use more efficient flight operations, including routing aircraft to locations where the exhaust trails (contrails) cause fewer problems.

2. Alternative Non-Carbon Fuels

Secondly, we can fly without using hydrocarbon fuels, possibly using hydrogen or ammonia as the energy carrier. This is attractive to eliminate carbon but requires a major rethink of aircraft design and fuelling infrastructure and so is very much a longer-term option.

3. Abatement

Thirdly we carry on burning hydrocarbon-based jet fuel but with the carbon sourced from feedstocks that originated from plant-based materials (and even from CO2). This would mean the carbon in the CO2 we emit during flight originally came from atmospheric CO2. The flight would bring the carbon round in a circle to its origin, with atmospheric CO2 photosynthesised into plants, which is then processed and burnt to produce CO2, and so on.

SAF Provides Abatement Ability

This third change is where SAF comes in. Simply put, a jet fuel that contains 10% sustainable carbon will produce 10% less net CO2 emissions (excluding processing, transport and other costs).

SAF offers this huge advantage: it effectively brings about a net CO2 reduction without changing the aircraft or airport infrastructure.

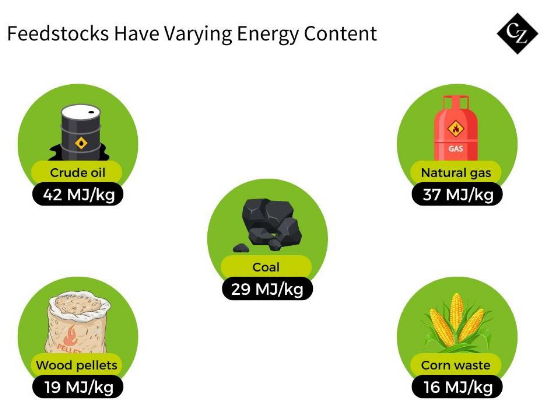

What a great win! However, it is not without challenges. Rather, it pushes the obligation for change away from the airlines, aircraft builders and engine manufacturers and onto the fuel suppliers. Suppliers now need to switch from crude oil, which has an energy content of around 42 MJ/kg to feedstocks such as forestry residues and corn waste, which have perhaps 16 MJ/kg.

Vegetable oil, converted via the HEFA process (D7566 Annex A2) has an energy content very close to crude oil, but many of these are used in food production and may therefore be disallowed from being considered sustainable.

The energy content of jet fuel can only be reached by intensive processing — including the use of hydrogen. Such a significant specific energy upgrade, from 16MJ/kg to 42 MJ/kg, is costly and so this explains why scaling up is taking time and why SAF remains well below the 1% penetration level.

Next time we will look at how we calculate a specific CO2 reduction for a particular SAF, and who does it.