World cotton production, totalling around 25 million tonnes annually, is heavily influenced by five key countries that account for over 70% of the global output. As the demand for sustainable practices grows, the global cotton supply chain is actively investing in sustainability initiatives to ensure a more environmentally friendly and socially responsible industry.

Introduction

Cotton is the most valuable non-food agricultural product in the world and is one of the most extensively cultivated and traded commodities. Cotton accounts for just under a quarter of all global fibre production, with over 25 million tonnes of cotton produced globally. Applications range from textile products and home furnishings to medical products, with approximately 57% of cotton used to make clothing.

Cotton contributes to the economies of multiple developing nations, most of which are based in Asia. However, the market faces several challenges including competition from synthetic fibres and the sustainability of production.

The cotton supply chain is complicated due to the number of stages involved, the links between them and its geographical fragmentation. Parties at each stage often act alone with limited information sharing and collaboration.

What is Cotton?

Cotton is the soft fluffy fibre that is harvested from cotton plants in a seed coating called a cotton boll. Inside the cotton boll, around eight cotton seeds are attached to the white cotton fibres. Cotton is almost entirely made of cellulose. Cellulose is found in all plants in varying amounts, but cotton is one of the purest forms of cellulose.

The quality of the cotton fibre varies geographically and between plants. It depends on the type of fibre used and how the cotton product is produced, for example, the type of weave and the thread count.

The staple of the fibres refers to the fibre length and can vary. Approximately 90% of cotton production is short staple cotton, known as Upland cotton. The longer the fibre, the better quality the cotton.

Egyptian cotton is often singled out due to its strength and softness, which is why it is often used to produce luxurious bedding and towels. It is the highest quality cotton fabric, as it has the longest fibre length. Egyptian cotton is grown within the Nile Delta in Egypt, where the climate is hot and dry, however cotton with similar characteristics can also be grown in India and Peru.

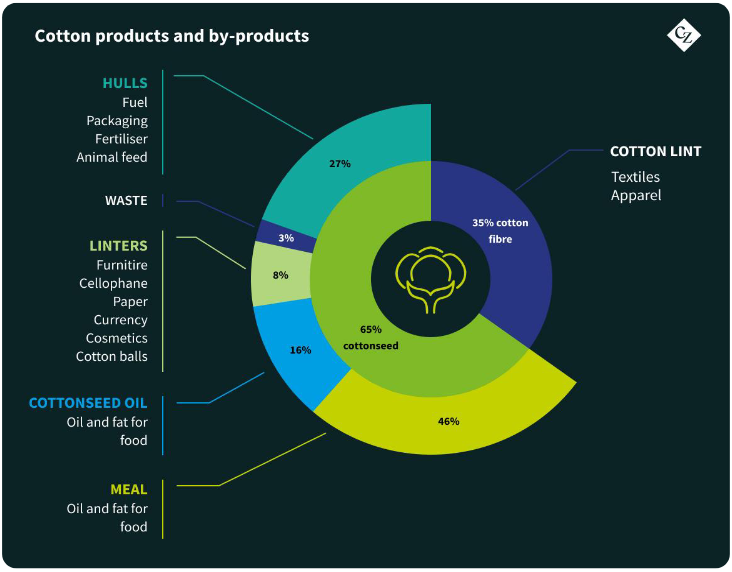

Cotton can be used to create a variety of products, the majority of which are used to make textile or apparel from cotton lint. Cottonseed is the waste product derived from the process of separating the lint from the seeds in the boll. This can be crushed to make cottonseed oil, meal, linters or hulls. One of the most used by-products is cottonseed oil for edible food products such as cooking oil and margarine.

Where Does Cotton Grow?

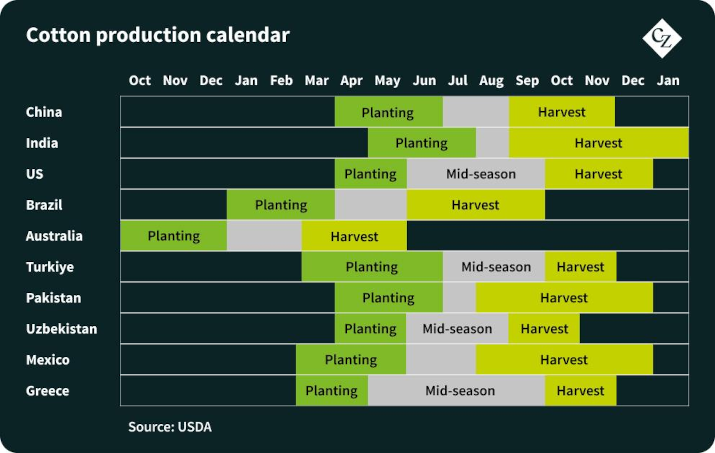

Cotton production takes place in over 70 countries around the world and the time cultivation depends on the climate in each country.

Source: International Cotton Advisory Committee

Crop rotation with wheat or corn is popular, depending on the season, to increase soil fertility and structure, which in turn increases the crop yield.

The first stage includes preparing the farm and soil for planting. The plant then grows for around four months, requiring periodic watering. It will then develop a flower before ripening into a fruit and presenting the cotton bolls.

It is at this point the crop is ready to be harvested either by hand or mechanically, depending on the location and resources available. Cotton is grown in both tropical and subtropical regions where there are consistently long periods of warm weather and moderate rainfall.

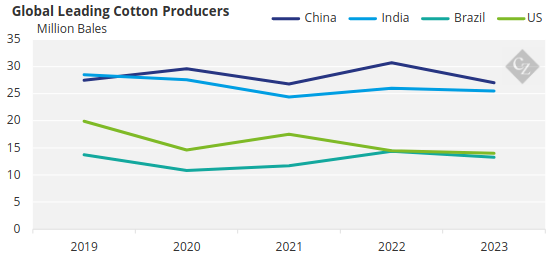

Leading cotton producing countries include China, India, the US and Brazil. These four countries along with Australia are responsible for over 70% of the global cotton production.

Source: USDA

Production in the US has recently decreased due to droughts that have swept across cotton producing states in recent years, putting cotton production at a historic low. Meanwhile, Brazil has increased its cotton production, due to the favourable conditions and productivity.

Source: OECD – FAO Agricultural outlook

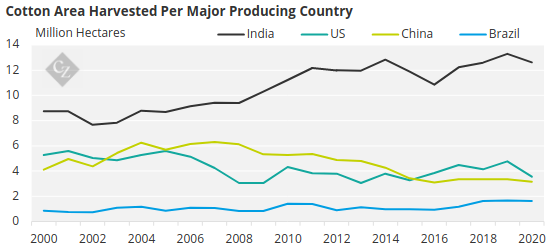

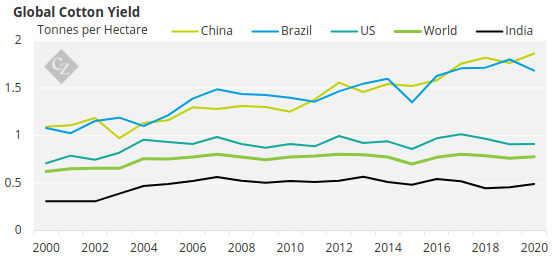

The cotton area in India is considerably larger than the other global cotton leaders, but India’s yield is well below the average, due to farmers leaving wider gaps between rows of plants to allow for pest control and for bullocks to traverse.

Source: OECD – FAO Agricultural outlook

The cotton yield has increased in both China and Brazil due to modern farming techniques and favourable conditions.

The Cotton Supply Chain

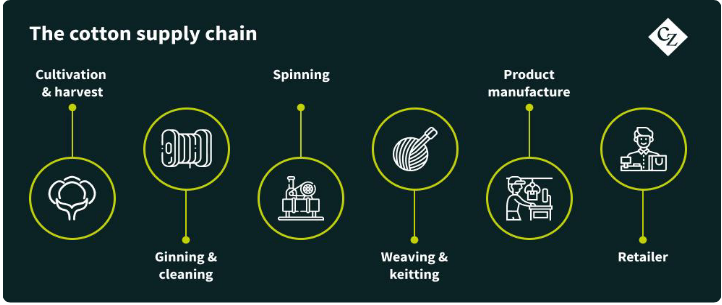

The cotton supply chain starts with cultivation and harvest. The cotton fibres are then ginned, where they are cleaned and separated from the seeds. This stage determines the quality of the cotton fibres, which will have implications for the downstream processes. It is during this stage that the cotton is formed into bales, which can then be traded as a bulk commodity and transported around the world.

The ginned cotton is then spun, while the cotton bales are transformed into yarn. This yarn can be further processed into fabric through weaving or knitting, before being passed onto the product manufacturer where it can be used to create an array of products, from clothing and home textiles to medical supplies and industrial materials.

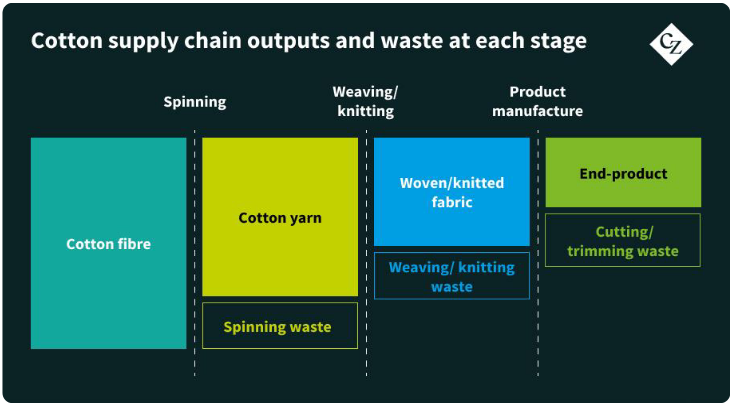

At each stage in the manufacturing process there is an output and a waste byproduct, meaning the output weight is lower than the input. The weight of the output product depends on the yield at each stage.

Who Consumes the Most Cotton?

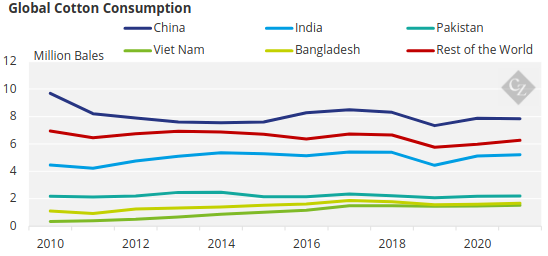

Cotton consumption is driven by the demand for textiles and apparel, which has been steadily increasing. Cotton consumption has been increasing in developing countries thanks to both rising income and a growing population. Meanwhile, developed countries with mature markets may exhibit stable or fluctuating consumption patterns.

Cotton consumption is calculated at the spinning stage, where the cotton is transported to the cotton mills and spun into yarn. Cotton mill use depends on the global demand for textiles along with competition from other textiles such as polyester and synthetic fibres. China represents 30% of the global cotton mill use, followed by India and Pakistan.

Source: OECD – FAO Agricultural outlook

How is Cotton Traded?

The global cotton market is a significant component of the textile industry, with trends influenced by various factors, including production levels, consumption patterns, trade dynamics, and economic conditions.

Cotton is a globally traded commodity and production is dominated by four countries, China, India, the US and Brazil. However, most of the cotton produced in China is kept in the country, making the largest cotton exporters the US Australia, Brazil and India.

The majority of cotton is traded after the ginning stage as cotton bales, which are shipped in containers. The largest trade flows are from India to Bangladesh and from India to China. About 10 million tonnes of cotton are exported each year, with the top four exporters accounting for 80% of global exports.

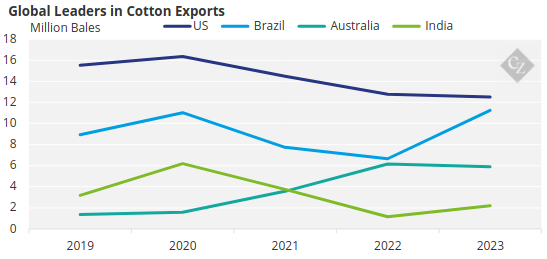

The US is currently the largest cotton exporter, with Brazil just behind. In recent years the difference in exports between the two countries has been decreasing, due to droughts in the US and preferable conditions in Brazil. Brazil is set to overtake the US as the largest global cotton exporter. Brazil’s cotton production is expected to continue to grow due to modern farming techniques and favourable conditions and the US is continuing the battle harsh conditions.

Source: USDA

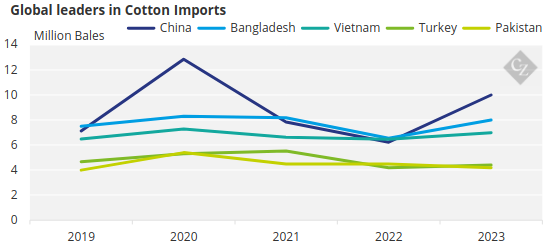

The largest importers of cotton are China, Bangladesh and Vietnam. The top five importers of cotton account for 75% of global traded cotton.

Source: USDA

What is Sustainable Cotton?

The main challenge with cotton production globally is the complexity of the supply chain and ensuring this is both traceable and sustainable. The cotton supply chain has several stages, with each of these processes often taking place in different locations and being carried out by different parties. As cotton is passed between parties, the traceability is often lost, so once the final product is produced there is often no knowledge of the cotton’s origin.

Sustainability is also a major opportunity for cotton. Sustainability is becoming ever more important in people’s day to day lives and majorly influences people’s decisions of what to buy and companies’ decisions on who they work with. This opens the opportunity for businesses to invest in sustainable cotton.

Sustainability initiatives have introduced the mass balance system, meaning the retailer has sourced a certain amount of cotton from the selected cotton farmers, but there might not be any sustainable cotton in the final product. This is less costly than a fully segregated system, but it does not provide a traceable supply chain.

Brazil’s cotton initiative ABR is partnered with the Better Cotton Initiative and is a great example how to take advantage of the opportunity in sustainable cotton. About 86% of Brazil’s cotton production licensed by the Better Cotton Initiative. The Better Cotton Initiative (BCI) accounts for 22% of global cotton production, grown in 22 countries around the world.

Organic cotton is a more sustainable option for the environment and the farmers as it brings financial benefits. They can charge a higher price, and organic practices have a positive impact on their land. Organic cotton is grown without the use of pesticides or synthetic fertilisers, which can be harmful to the environment during both use and production. Instead, farmers select a more natural method to grow cotton, aiming to build healthy soil and reduce emissions. This has multiple benefits including increased soil health, reduced water usage by up to 90%, a lower energy demand and lower CO2 emissions.

Another great opportunity in the cotton market is cotton by-products. After the ginning stage there are two main outputs — cotton lint for fabric production and cottonseed. Cottonseed can be used to make a number of different products, for example cottonseed oil, cotton linters and animal feed. These by-products can generate further revenue.