A Quick Recap

In the first two Opinions in this series, we examined how aluminium is produced and traded, and we discussed it uses. We also looked at the energy equations in producing aluminium and discussed the importance of recycling. In this report, we’ll cover the development in technology for canned beverages.

Aluminium’s Place in Food and Beverage Canning

The aluminium can’s origins are rooted the brewing industry, and, in its father, the steel can. Tin plated steel cans now amount to around 25% of global production with aluminium taking the remaining 75%. The total global production of both is around 400 billion units per year. On top of this, aluminium is used in some food cans (although tin plate dominates this sector), as well as ever-growing niche uses such as for aluminium aerosols and bottles.

Today, the aluminium canned beverage industry uses precision engineering similar to that found in the car, aircraft and space industries combined with high-speed production processes and logistics. Typically, in the modern production process, only one in perhaps 75,000 modern aluminium cans are defective.

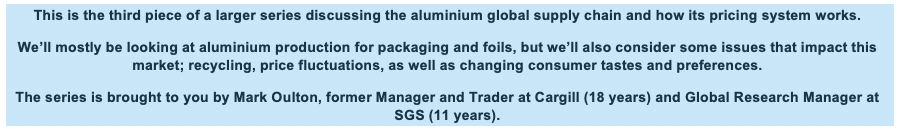

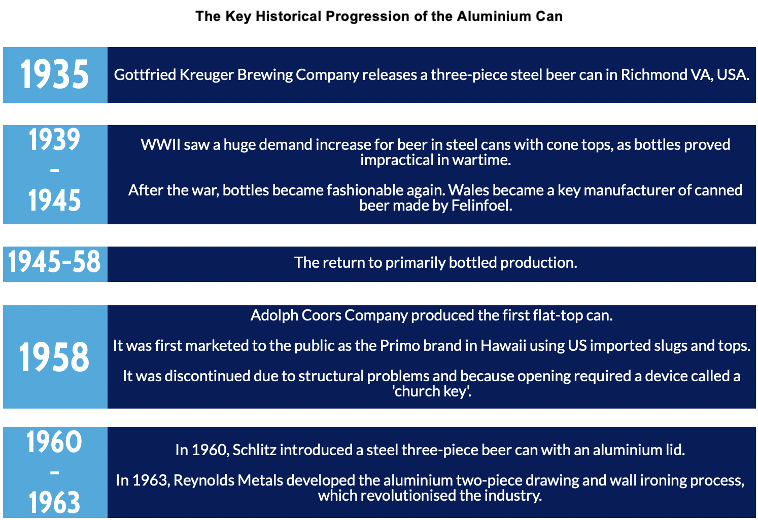

Origins in Brewing Beer and Steel Containers

Prior to 1935, bottles, barrels, earthenware jars (etc) were the main receptacles for carrying and storing beverages. It was World War II, and particularly the needs for beer that could be distributed to the troops worldwide, that prompted the first growth in aluminium beverage packaging. There had been patents filed much earlier for beverage cans, but the pressurized nature of the contents caused technical difficulties.

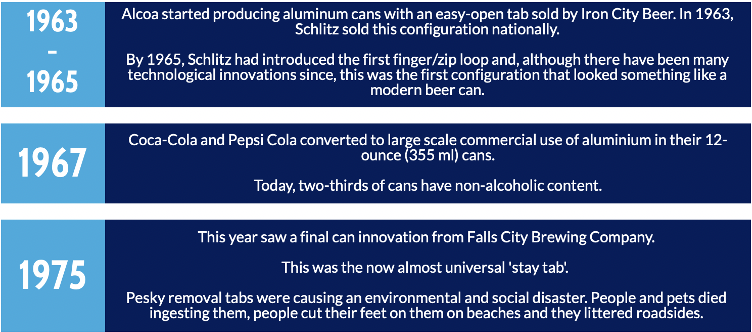

Precision Technology

The modern beverage can is a miracle of engineering, both in design and in the production method.

The product that arrives at the processor intake is called ‘aluminium coil stock’. It’s something similar to a roll of thin aluminium that has been flattened at room temperature (250 microns –0.025 cm/ 0.01”) and is easily identified as a 3 series (AA3 followed by 3 numbers) such as AA3004. The stock typically weighs 9 tonnes and is 1.5 metres wide. The basic process is then somewhat similar to the 1963 Reynolds Process.

Inspection processes are built-in at several stages of the process, including at the final stage, which includes a test for any leakage. The cans are now ready for palletizing and onward distribution to the beverage manufacturer to insert the drink and apply the top. The tops need to be of a stronger material, although the thickness remains similar. This is typically done by adding 4.5% magnesium (Mn) and 0.3% manganese (Mn) alloy from the AA5 series such as AA5182.

The final product weighs around 13 grams (0.47 ounce), which means metal usage has been optimized as well as freight and stacking characteristics. This is a product that, when filled, has massive internal strength and although under normal conditions this supports pressures of 2.07 bar (30 psi), it can withstand 90 psi (for extremes of hot temperature for example). And yet, when empty, they can easily be crushed. Lack of pressurization in non-carbonated beverages has been solved by adding nitrogen.

The speed of many of the operations in the process is dazzling. For example, the redrawing, ironing and doming process takes 1/7th of a second per can and external decoration can operate up to speeds of around 2000 cans/minute.

In conclusion, the combination of science, to avoid waste and make the cans thinner, technology, to make the process faster, and more accurate diagnostics for a more efficient process, means that the modern-day anatomy of an aluminium can is often used as an example of high-quality precision engineering.

One Size Does Not Fit All…

The size and shape of the aluminium can is becoming increasingly varied, with new terminology like slim, sleek and squat as well as many different standard sizes for different countries.

In the next report, we will explain more about how the beverage can is filled and the top is applied by the beverage producer. We’ll also look at the different types of consumer offerings.

Other Opinions You May Be Interested In…