Insight Focus

Barley is a grain used for malting and feed. It is grown as a winter or a spring crop, with the highest-quality varieties planted in spring and careful monitoring needed to meet brewing and distilling standards.

Barley is a grain, grown across the globe, with uses mainly as livestock feed and to produce malt, hence the term ‘malting barley’. The process of malting is most widely associated with the use of barley in beer as well as distilled malt whiskey, together with a number of other smaller uses.

The aim of malting is to convert the insoluble starch within the endosperm to more useable sugars needed for the fermentation process of brewing or distilling.

Methods used today in the malting industry have origins dating back 6,000 years or more, when the Egyptians were known to have been brewing beer.

The Barley Grain

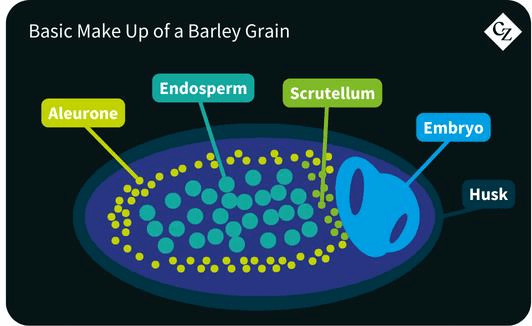

The picture below shows the basic make up of a barley grain.

The ‘husk’ is the protective layer around the embryo and endosperm to prevent damage.

The ‘embryo’ is the ‘germ’ which is the part of the seed which ultimately grows into the roots and shoots of a new plant.

The ‘endosperm’ is made up of insoluble starch, which converts through enzyme activity once moisture is made available to become a food source for a new growing plant.

This is the critical ‘modification’ part for a maltster, where the enzyme activity begins but is stopped, using heat, prior to the starch being fully converted to sugars as food for the growing roots.

Cultivation of Barley

Malting barley can be cultivated as a ‘winter’ or ‘spring’ crop, usually within a cereal based farming rotation.

‘Winter’ barley is planted in the autumn months, allowing it to germinate and establish a green carpet of small plants across the field in advance of the harsh winter months.

It will lie dormant through freezing temperatures, surviving happily under a blanket of snow, until the warmer weather of spring allows it to continue through its growth stages. It is harvested in the early to mid-summer months (July in the UK).

‘Spring’ barley is sown once the soil temperatures begin to rise following the cold of winter. It will then race to maturity with harvest in the mid to late summer months (August in the UK).

Winter barley varieties will generally be higher yielding than their spring counterparts. The highest quality malting barleys are spring cultivated varieties.

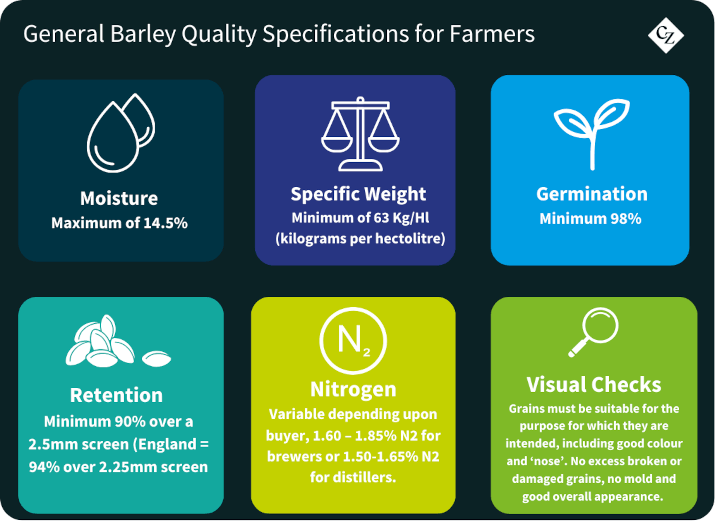

It is critical for farmers to ensure that the required quality criteria are carefully monitored to comply with the needs of the barley’s end use. Failure to meet these standards will result in the barley being destined for livestock feed at a greatly reduced value.

The quality specifications will vary depending upon type, variety and end use of the malt. The following is an example of general requirements for a farmer seller.

The Malting Process

The principle of malting is to allow the barley to begin its germination process and then arrest it by the introduction of heat. The applied heat will allow the grain to be ‘cured’ and adjusted to allow the appropriate flavour and colour for the brewer or distiller.

Steeping

This step generally takes place over a period of two to three days. The grains are subjected to several water emersions which will in effect awaken the dormant seed to begin the initial germination process. The expertise of the maltster here is to achieve the correct combinations of water and resting period in air while not drowning the grains.

Germination

Taking place over four to six days, the grains begin their germination. It is vital that there is adequate air, blown through the bulk from the underside combined with turning of the grains to keep them loose.

The aim of this stage is to enable the grains to germinate with sufficient enzyme activity to breakdown and begin the modification of the starch but not to allow the endosperm to be converted to a source of food for the roots. It is thus arrested with the application of heat at this critical point.

Kilning

This process applies warm/hot air to the grains to arrest germination and impart colour and flavour to the malt depending upon the final requirements of the brewer or distiller.

The malt is initially dried and then ‘cured’ at a high temperature to stop any further changes to the grains.

Kilning is a tightly controlled process, which will vary depending upon the desired end malt.

Removing the Rootlets

The last operation is removing the small rootlets from the grains to produce the final malt ready for transportation onto the brewer or distiller.