Insight Focus

The EU has approved EUR 500 million for chemical recycling. It supports converting contaminated plastic waste into recycled PET. Unlike traditional recycling, it includes mixed plastics, ensuring a steady supply to meet growing legislative demands.

With the latest news that the EU Commission has approved EUR 500 million in funding for a French chemical recycling scheme, this process is under the spotlight as a positive contributor to the circular economy.

Under EU State Aid rules, the funding has been given to support chemical recycling for the conversion of contaminated plastic waste to create a raw material that ticks all the ‘recycled PET’ boxes. This means a wide range of post-consumer plastic waste can be included, including notoriously difficult-to-recycle items like food trays and textiles containing polyester.

While the EU funding is destined for all sorts of companies that are involved in chemical recycling, it is of great interest to the PET industry, specifically converters and plastic packaging producers, as it highlights the importance placed on this process and the assumed commercial viability of this sustainable solution.

What is Chemical Recycling?

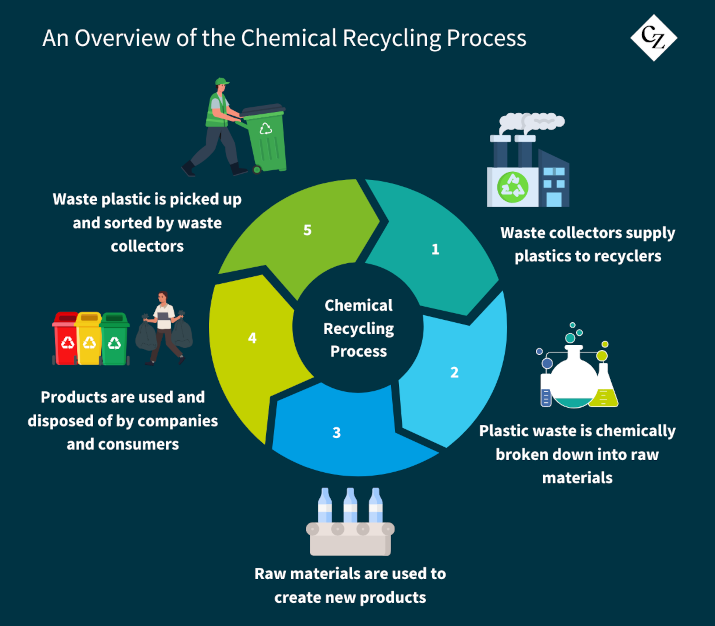

Chemical recycling is an advanced process that breaks down plastic waste into its basic chemical components, so that waste plastic can be turned into new plastics, and then into new products, essentially creating an endless loop.

Whereas ‘traditional’ recycling has limitations when contaminants are introduced into the recycling stream—such as food trays with leftover food waste or bottles containing certain additives or colourants—chemical recycling is not phased, even when everything is mixed together. This ensures a constant, reliable supply of recycled PET.

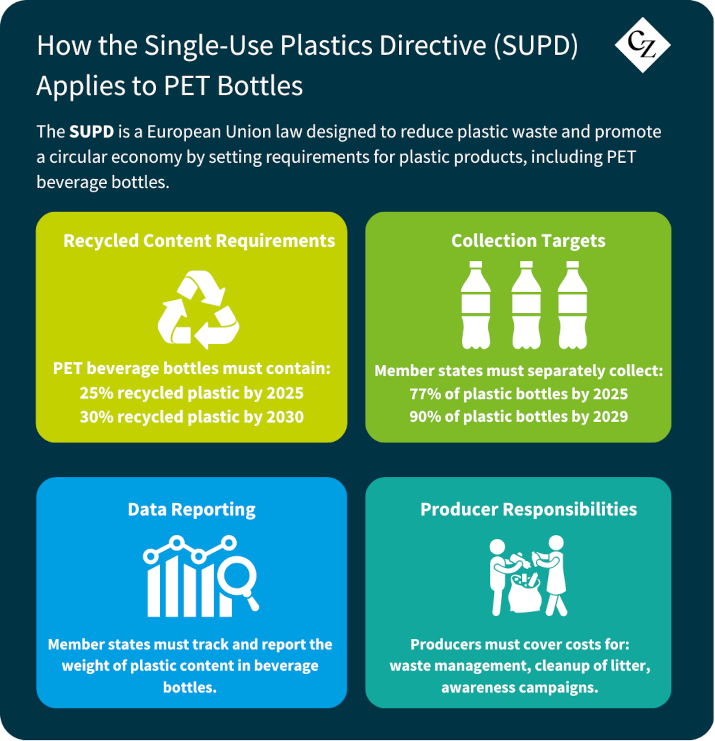

This ‘easy process’ is valuable because there is a huge demand for recycled content, driven by ever-evolving legislative changes. Currently, the EU’s Single-Use Plastics Directive (SUPD) mandates that by 2025, PET bottles must contain at least 25% recycled content, increasing to 30% by 2030.

Additionally, California’s SB 54 requires a 25% reduction in single-use plastics and a 65% recycling rate for such items. However, there is no legislation about where that recycled content should come from.

For plastic converters and PET and rPET packaging producers, this legislation is encouraging investment in chemical recycling technologies as well as promoting other methods to obtain the necessary volumes of rPET.

As every player across the packaging supply chain is embracing their sustainability responsibilities, integrating chemical recycling makes sense, as it aligns with sustainability goals of both customers and stakeholders by helping to support the circular economy. Moreover, it is made easier to embrace when there’s the possibility of EU funding to support the initial investment.