Insight Focus

- The shipping industry is facing unprecedented environmental and operational challenges.

- But technological advances can help the industry operate more efficiently.

- We spotlight some of the most innovative technologies available for the shipping industry.

Shipping Industry Requires More Efficiency

If the past few years taught us anything, it’s the ripple effect of a tangled supply chain. Through the Covid lockdowns, port, labour and supply issues stretched shipping firms to their limits and impacted on economic growth.

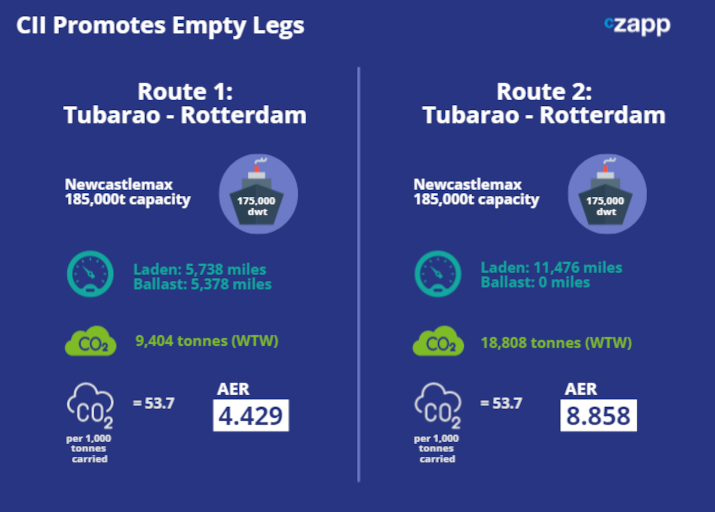

Now, even as this disruption clears up, shipping firms are facing more roadblocks. New emissions regulations have come into force that in some cases incentivize slow steaming and ballasting.

More than ever, the industry needs technology to generate efficiencies. Here are just some of the technologies emerging to help improve efficiencies in shipping.

1. Goods Distribution

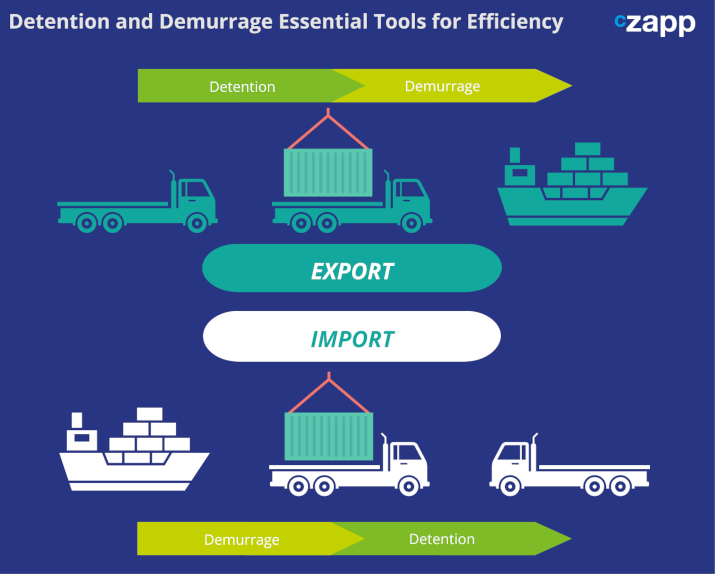

The issue of demurrage and detention became a huge trial for many shipping and logistics company recently. While firms are generally given a grace period to load and unload vessels and containers, the industry needs to incentivise fast turnaround, which is where demurrage and detention fees come in. In a normal environment, the fees work well to reduce congestion and create faster turnaround times within the shipping industry. But heavy port congestion in 2022 distorted the charges, with import-export firms being charged for retaining containers they were not physically able to return. Read more about the phenomenon in our analysis.

One of the silver linings to come from the situation is the emergence of technologies such as Portchain Connect. Portchain Connect uses AI to improve berth alignment – meaning it can prompt ports to move around containers into a more logical order depending on when they are due to leave the port. This will reduce spoilage of perishable goods, reduce truck and vessel wait times and save costs.

2. Workforce Scheduling

Workforce costs are typically a company’s biggest expense. The average company spends about 64% of total company costs on labour, including employee salaries and benefits. And a huge factor behind 2021’s supply chain backlogs was staffing issues, whether that was sick leave, strikes or lower capacity due to Covid restrictions.

Traditional workforce scheduling tools are also set up for retail and hospitality industries but do not account for huge, multi-skilled workforces like those that exist in shipping. And the available labour pool has shrunk. Since the pandemic, studies have found that workers prioritise jobs for their work-life balance even over the salary offered. This trend has reduced the traditional maritime labour pool as people seek more flexible jobs that don’t require long shift work or unsocial hours. Scheduling and forecasting technology such as Athena and Portunus can help solve these problems, and, unlike many scheduling platforms, these are specifically designed for the maritime industry. The Athena scheduling tool uses predictive modelling to assess workload, availability, skillsets within that available labour pool and even weather variables to give ports an idea of their scheduling needs.

The technology has been rolled out across some European ports and, according to the company’s founder Cato Davies, can reduce labour costs by up to 8%. “Because there is such a shortage of workers at these ports, they rely on contractors and overtime,” he explained. “Normally, they just find the first combination that works but we look at the probability that every operative will hit overtime and we are able to utilise the available skills more efficiently.”

3. Improved Vessel Inspection

Safety is paramount to the smooth operation of the shipping industry. Not only does maritime shipping carry trillions of dollars’ worth of goods, but also crews of up to 30 people. And as the fleet ages, it is important that more regular inspections are carried out to ensure nothing goes wrong in the middle of the ocean.

The problem is that there is not enough staff or time to carry out the required number of inspections. One study showed that inspections are carried out on average once every six months, but even this takes up precious time and resources. And that’s not to mention that some inspection requirements can be dangerous, such as hull cleaning and inspection work.

The robots are not quite taking over but they could offer quite a reliable helping hand when it comes to inspections. Shipping company HMM has begun replacing human labourers with robots in high-risk environments. And Shiptest has developed robots that are placed on the hull and use a laser weld tracking system to assess welds and map corrosion.

As well as working more efficiently and safely, the technology can eliminate costly human error and carry out menial tasks that staff may find boring. The presence of inspection robots will only become more prevalent in shipping as more uses can be found for them on board.

4. Cargo Check Facilitation

It is not just the ship itself that needs to be inspected, but also the cargo it is carrying. On land, some grocery and retail chains have begun rolling out smart scanners that allow customers to bag goods and walk out, with the scanners recognising which goods have been selected and charging the customer’s card the appropriate amount.

Well, this technology is also being applied to the maritime industry to speed up inspections and reduce wait times. And given the rise in sanctions globally, it is important to ensure that cargoes really are what they say they are – although it is impossible to inspect every container that reaches port. But limited resources mean that, if a cargo is flagged for extra inspection, it could take five to six extra days to complete.

But real-time automatic identification of goods can help streamline the process and give crucial extra time for human inspections. Technology has been developed that allows AI to run optical character recognition (OCR), which can detect, recognise and link alphanumeric or symbol-based characters with the corresponding information, whether it be container codes, barcodes or even vehicle number plates.

Imaging technologies such as Matrox can scan faster than is humanly possible and under challenging visibility conditions, which allows ports to track inventory and even carry out complex quality inspections. However, it is worth noting that a human touch will probably always be needed given that AI tends to struggle under complex or unknown conditions.

5. Enhanced Route Efficiency

Shipping has always been fraught with danger. In response to several fatal shipwrecks, Vice-Admiral Robert FitzRoy was appointed Meteorological Statist to the Board of Trade in 1854 – charged with collecting and analysing weather data at sea. The Met Office, as it is now known, grew to become the UK’s national weather service and over the years it has become a vital information source for seafarers. But even in recent years as meteorological forecasts have become more reliable and advanced, climate change has thrown a spanner in the works as weather events become more extreme.

San Franciscan company Sofar Ocean Technologies has now developed the Wayfinder platform that collects 200,000 real-time ocean observations that have proven to be about 40-50% more reliable than government models. This data is then used to optimise a vessel’s route, protecting it from adverse weather events, helping reduce fuel consumption and in turn reducing emissions. Hundreds of thousands of routes are considered and companies can even make modifications based on specific business or safety constraints. The company says customers save an average of 3-5% fuel and time per voyage, generating CO2 savings of tends of thousands of tonnes across a fleet.

6. Collaborative Port Calls

“Steam Fast, Then Wait” is a key principle used by the maritime shipping industry. The practice is pretty self-explanatory, but relatively wasteful. Ships are incentivised to get to their destination port as quickly as possible – or “at utmost dispatch” — where they then must wait at anchor until there is capacity to unload. In fact, according to the Green Voyage 2050 report, dry bulkers and tankers spend up to 10% of their life at anchor. Not only does the practice waste time, but it incurs demurrage fees and is not particularly friendly to the environment.

The Blue Visby Solution has been formed through a consortium of 25 shipping and commodity companies, including BIMCO, Lloyds of London, Bureau Veritas and the Ocean Conservancy. The platform identifies groups of ships heading to the same destination port and applies an algorithm to their journeys. Blue Visby can then stagger the arrival times of the group while taking into account optimal steaming speed, ship performance and weather, alongside other factors. This then reduces port congestion while also ensuring vessels are performing the best they can to lower emissions. Slow steaming generates fewer emissions so optimising arrival times at port could save up to 200 million tonnes of CO2 each year, according to some findings.

7. Autonomous Driving Tools

In March 2021, one of the world’s biggest shipping channels was blocked for six days after the Ever Given container ship ran aground and ended up wedged across the waterway. This created havoc for the global shipping industry and prevented an estimated USD 9.6 billion in trade each day. While strong winds were blamed for the issue, Egyptian authorities said that “technical or human errors” may also have been involved. And the event proved costly – Egypt detained the vessel and its crew until a $550 million settlement was paid.

While the issue of human error will always be present in shipping, more and more steps are being taken to automate driving processes. You’ve heard about autonomous cars and trucks, but what about autonomous ships? Implementing the same technology in the shipping industry as exists in road transit is much more complex due to scale, weather and other variables. But some advances are being made to transition towards autonomous vessels. Shipping Technology has launched the ST Brain, which collects all sorts of data, including radar, river pilot, motor management, GPS and AIS. While it doesn’take over, it can then provide autonomous lane assist statistics to the captain. Other companies such as Kongsberg provide integrated sensor technology and automated collision avoidance for unmanned ships. Going forward, integrating more machine learning into manoeuvring systems will allow vessels to remain on course with relatively little human input.

8. AR for Training, Ship Design

Right now, most seafarers can only access hand-on experience on board a ship when they first set foot on board. But now, several maritime academies, including the Royal Norwegian Navy Academy, are incorporating new technology into their curriculum that could allow seafarers to have hands-on experience with no risk.

Virtual Reality (VR) and Augmented Reality (AR) have applications that reach far beyond video games. For shipping companies, the technology could be an effective and efficient way to provide more in-depth training on board vessels. And when seafarers do finally set foot aboard, they are likely to be more confident, reducing the risk of errors. Kongsberg has already launched the K-SIM simulation training series providing a range of simulated training, including in inland waterways, pilotage, towing and tugging and ice navigation.

Concluding Thoughts

- The development of new technology is moving faster than ever but the shipping industry still lags behind.

- Emissions reductions will be the key driver of technology adoption.

- With new shipping emissions regulations coming into force, efficiency will be key to remain competitive.

- As a result, green technologies and energy management tools will likely see the greatest demand in the coming years.

- But there is also scope to significantly reduce emissions through more innovative means, including workforce scheduling, AI and smart solutions.

- Smart shipping will become one of the most important priorities for shippers and ports but effective adoption is likely to take at least 10 to 15 years.