A Quick Recap

In our previous reports, we described the production process for aluminium ingots and then went on to explore the canned beverage market. It’s now time to consider the uses of aluminium in the market for foils.

Tin Foil Isn’t Made from Tin

In the early 20th century, tin foil was superseded by aluminium foil. Tin foil had a tendency to slightly taint any food products and was less malleable. Today, the words ‘tin foil’ are still heard because of this legacy, but it’s now actually made from aluminium.

The Early Years

Aluminium foil has a Swiss history. In 1886, J.G. Neher and Sons opened an aluminium plant in Schaffhausen (Switzerland) using the famous Rhine Waterfall to provide energy for the production process.

In 1907, his sons (Dr Lauber and Dr Neher) and Cie invented the endless rolling process and by 1911, aluminium foil was being used as the wrapper in Toblerone chocolate as it is today.

In 1912, the new foils were being used to pack soups as the Maggi brand (now part of Nestlé). And by 1913, across the Atlantic, the foils were being used to wrap candy bars and chewing gum and were even to put lightweight leg bands on racing pigeons.

From the 40s to the 70s

During the 1930s, aluminium foils started to appear in the Swiss and German dairy industries, particularly for wrapping butter and cheese. In this time, household wrapper foils appeared in Europe and US. Next came inroads into the bakery sector.

In the Second World War, aluminium foil was in very high demand as it was dropped by bombers to diffuse radars. By the late 1950s, aluminium foil packaged products, such as coffee, began to replace some steel cans.

Pre-formed aluminium foil food packaging first appeared in 1948 and exploded in popularity with the growth of TV dinners and takeaway food in the 1960s. The containers (sometimes with compartments), are formed by applying mechanical air pressure to force the foil into shape using a die and cavity method.

The 1960s saw a major diversification of usages. The combination of paper outers with foil inners allowed the long-life storage of liquids such as fruit juices, UHT milk and soups (etc). It also enabled the development of tubes for toothpaste and cosmetics (etc).

It’s sometimes hard to imagine that, before 1958, airline food was usually served cold. This was followed by a period of pre-cooked warm food and then transferred to plates for serving from ‘five-minute ovens. It wasn’t until the 1970s that those ubiquitous economy class aluminium trays of hot food on a trolley appeared.

Production

The early stages of the production process, from mining up to the production of aluminium ingots, is the same as described previously for cans.

The foils are then made using rollers in a mill to produce the desired thickness, or alternatively by continuous casting and cold rolling. The latter method uses far less energy.

Unlike can stock, which tends to be uniform in thickness, foils have a much wider variety of specifications. For thinner grades of foil (below 0.025 mm), at the cold rolling final production stage, two delicate layers are put together, rolled and then separated to avoid damage. This is why the aluminium foil has both a glossy and a matt side. These foils can then be finished in different ways including coating, laminating, printing, embossing, scoring and cutting into different shapes and sizes.

A current growth area is the merging of the foil with flexible films to create lightweight and strong packaging.

Modern Uses of Aluminium Foil

In these reports, we’ll be concentrating on the use of aluminum foil in food, pharmaceutical and cosmetic packaging. This is usually divided into three areas; rigid, semi-rigid and flexible.

However, the foils have many other uses including:

- Building Insulation (heat exchangers, cable liners, heat/space blankets)

- Aluminium Foil Capacitors (computers and televisions)

- Geological Sampling (protecting rock samples from being tainted)

- Art and Decoration (the early 1960s silver-coloured artificial Christmas tree was a big hit)

Aluminium foils have valuable properties. They provide a complete barrier to light, moisture and bacteria, which are desirable properties in the food industry. This allows perishable goods to be stored without refrigeration and retain their aromas.

They are also used in the pharmaceutical industry because of their aseptic qualities.

Foils are also useful and practical in conventional fan ovens. They have great strength, flexibility, resistance to corrosion and are recyclable. They are also valuable for reducing waste. The Aluminium Association estimates that 29.51kg of coffee in steel cans requires 9.08kg of steel but only 4.08kg of laminated packaging (including the aluminium foil).

What About Microwaves?

This question comes up a lot.

Aluminium foil from a roll with a torn off strip can be used in a microwave. The concern is arcing, which can cause sparks, or even fire.

According to the USDA, food should never be completely covered by aluminium foil (it won’t heat up anyway). Instead, “small pieces of aluminium foil can be used to ‘shield’ areas of foods, such as poultry drumsticks and wings, to prevent overcooking”.

Also, make sure there are no sharp edges on the foil and there is a gap from the walls. Always check the instructions. We advise anyone who is unsure or interested in this subject to refer to this website.

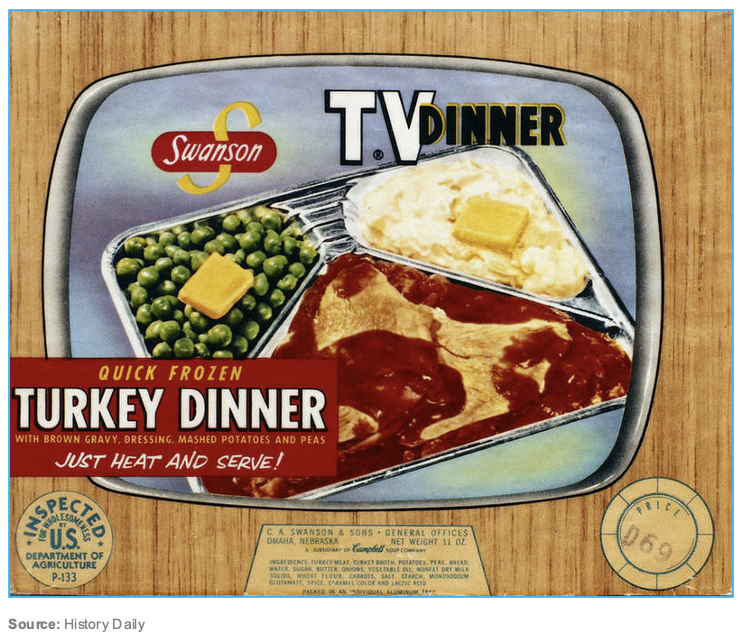

Similarly, aluminium trays can be used in a microwave. Here is the correct procedure according to Alufoil.

How is Foil Used?

The aluminium foils market consumes the same amount of aluminium (billets or ingots) as the cans market, both at 9% of total global usage (the remaining 82% is industrial, particularly for automobile and other transportation, as well as building and construction).

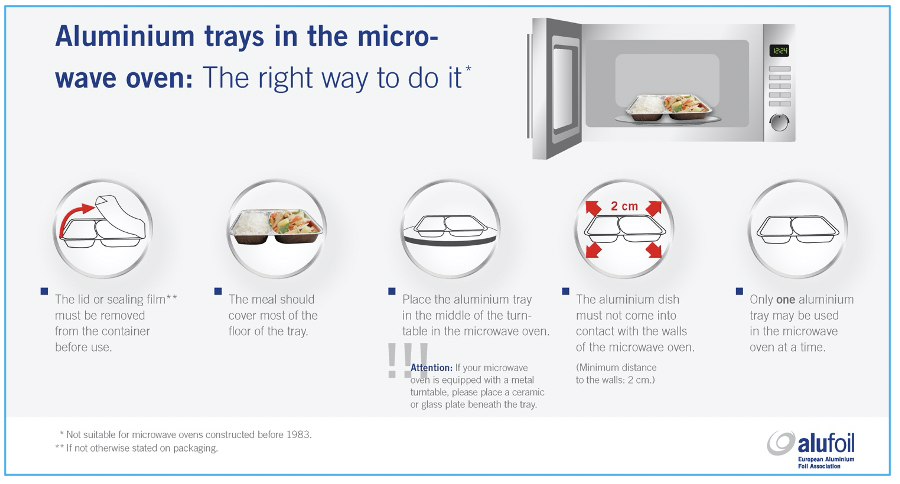

The global aluminium foils market is dominated by the consumer packaging sector and prior to COVID -19, the Compound Annual Growth Rate (CAGR) was around 5%, with some areas, such as pharmaceutical blister packs for medicines, exceeding that.

We will be considering the effect of COVID-19 on this sector in future reports.

The production figures in the consumer sector are staggering. The Aluminium Association estimates that globally, 7 billion aluminium foil containers are produced every year; that’s 220 containers per second. They also estimate that 13 billion packages of soups, coffee, pet food (etc) are candidates for replacement with flexible foil-packages.

To Conclude…

The aluminium foils market is a dynamic and growing sector. The convenience of these products, their solid properties, both for food safety and convenience, their recycling possibilities and wastage profile, all point to future growth.

Other Opinions You May Be Interested In…

- Aluminium: The Basics You Need to Know

- Aluminium: A Closer Look at its Carbon Footprint

- Aluminium: The Anatomy of the Can

- Aluminium: From Beverage Factory to Consumer

- Aluminium: New Can Manufacturing Technologies

- Aluminium: Consumer Beverage Trends