A Quick Recap

In previous reports, we’ve explained the aluminium production process, from its bauxite source to the point where a beverage has been put in a can (similar descriptions of aluminium foils will come in later versions). In this report, we will look at changes in manufacturer trends, consumer trends, and the links between the two.

Manufacturing Trends

1. Clearer Environmental Labelling and Associations

Whilst most consumers can recognise the recycling label on aluminium cans, few are aware that there is another story to be told. One less well-known offshoot for consumers has been the foundation of the Aluminium Stewardship Initiative (ASI), itself a creation of agreed climate change protocols in the aluminium industry. A key component is the environmental profile of the aluminium in the first batch of beverage can production (i.e. before recycled material is used).

Membership of ASI is offered in five categories of supporters: Associations, Civil Society, Downstream, General, Industrial and Production & Transformation. It’s an important forum and offers certification in different categories, such as the Performance Standard Certificate, and the voluntary, but encouraged, Chain of Custody Standard. The standards include emissions such as below 8 tonnes CO2-eq aluminium for smelters by 2030 (for production prior to end 2020). The certification also contains a raft of other requirements including labour and human rights and water stewardship. Currently, 47 member companies out of 83, mostly in Europe but in all continents, are compliant in their relevant fields. The list of members is also a useful guide to some of the leading companies in the aluminium sector.

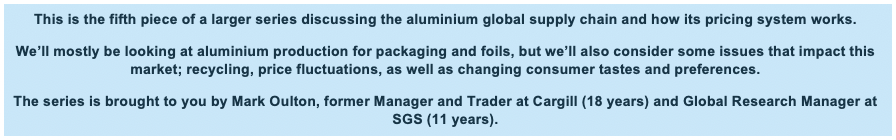

From a consumer marketing point of view, it would be very valuable to convey this information on the side of the can. However, there are some issues with this. The Carbon Trust (April 2020), has suggested two models.

The Carbon Trust was addressing the whole aluminium industry, but it sparks debate in the beverage sector.

In example A, this simple carbon footprint might be suitable for sectors, if it can be compared with others, but is wholly unsuitable for a beverage can as the consumer can’t relate to it without comparative information.

Example B will be familiar to many consumers from ratings on items, such as refrigerators, and does have comparative information. For an aluminium can, it takes up a lot of space and there is an additional problem that beverage can producers and downstream smelters are going to be resistant if they are using fewer environmentally friendly processes, such as using fossil fuels, rather than renewable energy sources. This is definitely a work in progress.

2. Resealable Cans and Others

Consumer research indicates there is a strong interest in a resealable beverage can. If only all that fizz could be kept for longer, or fruit juice oxidized slower after opening, as well as be resealed to avoid spills. On the beach, sand and insects can be kept out and the beverage kept fresh. It’s a key area of manufacturing and design research, as indicated by the number of patents being filed.

Some of the initial offerings, and still to be found, involved a resealable plastic tab.

Although this design is simple and functional, the combination of a plastic tab and an aluminium can makes manufacturing more difficult and the plastic and aluminium components need to be separated for recycling.

An improvement is to have an all-aluminium configuration and we will use two examples (of many) to illustrate this.

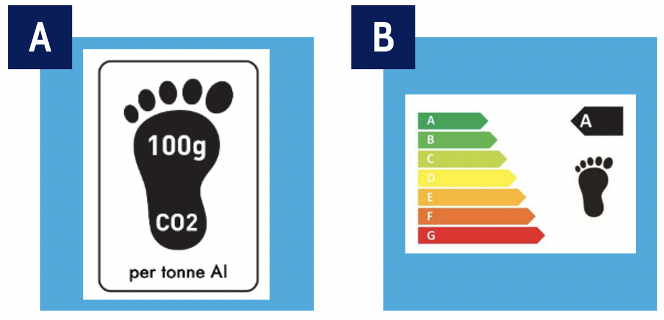

The first, is a patented system called SipNShut by SNSTech. Launched in 2019, this is an all-aluminium resealable system. The manufacturer claims, and is supported by several independent reviews, the product is easy to open and has no sharp edges. It also has a venting system to ensure a smooth beverage flow, it reseals, and has a tamper-proof mechanism. Importantly, modification to existing beverage fill lines are minor.

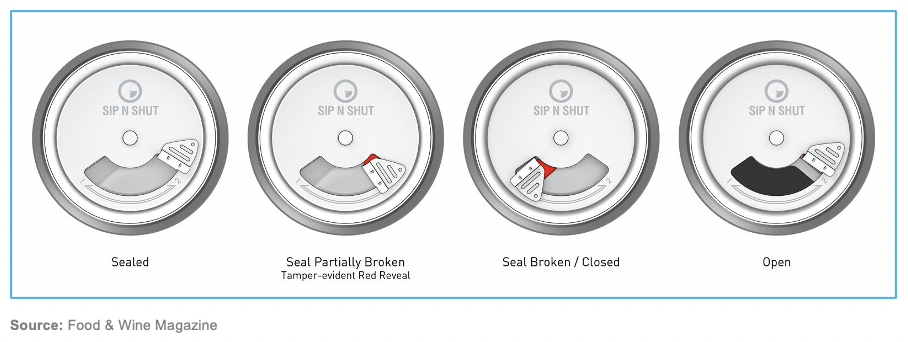

The second is a design currently under patent called PopSeal.

This intriguing design, if perfected or adopted, or something similar appears, might offer a glimpse into the future. Lightly striking the centre of the domed top cracks the opening seal. After opening, the cover returns to the closed position by a featherweight spring to prevent spillage and to release just enough carbonated gas to prevent re-sealing. Each time you take a sip, the can opens by the light touch of your lip. For those desiring a conventional always open can, a slightly harder push will allow it to remain permanently open. To keep some of the beverage until later, shake or turn the can upside down to seal the drink for reopening same as the first time. The inventor claims that manufacturing is much less complicated than a conventional tab system and also significantly reduces the weight of the can.

Other configurations that have been tried include a full aperture end, where the entire top can be removed to produce a drinking cup. It also has a use in solid contents such as nuts, dried fruit and jerky.

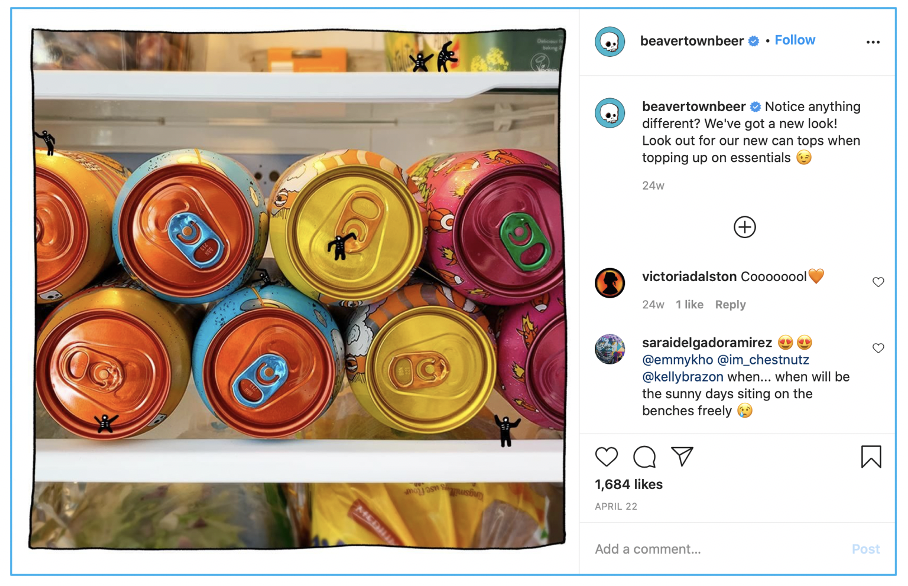

3. Using the Top in More Creative Ways and Inks

The can top has also become an area of improvement, primarily by the addition of colour to the tab. This aids identification of the product, especially where the product side is obscured, such as in a cardboard box or multi-pack with excessive wrapping. It also makes the whole can more aesthetically pleasing.

There is also work going into improved printing, from more advanced processes including using lasers. In one case, the beverage can producer is experimenting with fluorescent ink graphics. How spooky would that be at Halloween?

4. Reducing Trim and Weight

It’s important to note that metallurgists and engineers continue to work on reducing the quantity of aluminium to produce a can. The earliest aluminium cans weighed 0.09kg (3 ounces), but today, the weight is at least five times lower. Even minor modifications to the diameter of the lid, thickness of the wall, reductions in trim (the unusable part in the can manufacturing), all have significant savings in costs at volume in a very competitive industry.

In this report, we have mostly concentrated on manufacturing innovation. In the next report, we will look at the consumer end of the equation.

Other Opinions You May Be Interested In…

- NEW! Aluminium: The Basics You Need to Know

- Aluminium: A Closer Look at its Carbon Footprint

- Aluminium: The Anatomy of the Can

- Aluminium: From Beverage Factory to Consumer