Insight Focus

The first sugarcane to ethanol plant will be constructed in California’s Imperial Valley by Sugar Valley Energy (SVE). Higher sugarcane production is expected in the area as alfalfa growers will be incentivized to switch production streams to generate local feedstocks.

Sugarcane to Ethanol Plant Greenlighted

In what appears to be the first of its kind in the US, a sugarcane to ethanol plant will be constructed in California’s Imperial Valley by the company California Ethanol + Power.

A new 160-acre (65 hectare) bioenergy campus called Sugar Valley Energy (SVE) is planned to produce sustainable aviation fuel (SAF) from sugarcane feedstock. California Ethanol + Power said the project could produce up to 61 million gallons of SAF per year.

The production of SAF at SVE will help airlines in their quest to achieve net zero carbon emissions by 2050 as the campus is in a strategic location near seven Southern California airports and numerous general aviation and military airports.

Now in the final stage of development, SVE is comprised of an ethanol production facility, a bioelectric power island and a wastewater treatment facility. Products produced will include sugarcane ethanol for transportation fuels blending, renewable natural gas (RNG) and more.

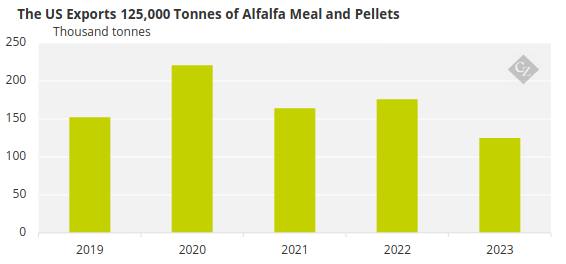

The sugarcane feedstock will be grown locally, directly controlled by SVE and fully contracted with nearby Imperial Valley farmers. SVE said it has developed a long-term feedstock program and envisions growers currently producing alfalfa for animal feed export markets will switch to sugarcane production.

Source: UN Comtrade

The project is expected by the company to support up to 15,000 jobs during construction and first year of operation, as well as approximately 2,000 agricultural jobs at full scale feedstock production.

The US EPA in January 2023 approved a pathway to make SAF and renewable diesel from sugarcane ethanol.

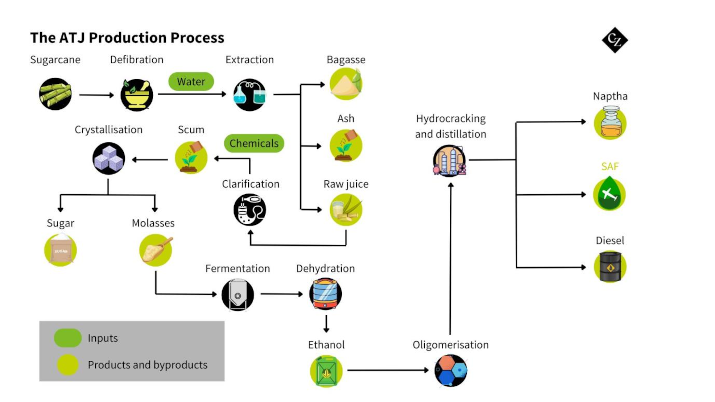

SVE’s SAF will employ alcohol-to-jet (ATJ) technology that was developed and tested by Pacific Northwest National Laboratory, a unit of DOE’s National Laboratory. The process converts ethanol to Synthetic Paraffinic Kerosene and Synthetic Paraffinic Diesel.

The company said the process is an approved pathway to produce SAF in accordance with ASTM D7566 Annex A5, which permits blending up to 50 percent with conventional jet fuel.

Global SAF Market Expected to Boom

A recent research report from Rabobank indicated that the global demand for SAF will grow from 2.5 million tonnes in 2023 to 25 million tonnes by 2030. However, airlines are a being a bit slow to adopt the fuel blend, according to some reports. The adoption of SAFs by airlines has been disappointing in the eyes of some industry watchers.

As more SAF production comes online over the next several years, the increase in supplies will likely create economic incentives for greater airline consumption.

And ethanol from sugarcane may have an advantage as a preferred product for blending with conventional jet fuel. SVE says its ethanol from sugarcane will have the lowest carbon intensity of all feedstocks for SAF in the state of California.