Insight Focus

Malting barley is a challenging, niche crop to grow. Proper cleaning, drying, cooling and storage are crucial to preserve quality and protect premiums. Any failure in these steps can result in significant financial losses.

Malting barley is very much a niche crop with many hurdles to navigate for the farmer grower.

Having spent months carefully planning and growing a good crop, it is all too often a sad sight to see the wasting of good premiums and the associated financial losses incurred due to poor attention to detail post-harvest.

Pre-Harvest

As mentioned in our previous article, it is imperative that any quality malting barley grower has access to the necessary on farm or commercial grain conditioning and storing facilities.

In the weeks preceding harvest, meticulous cleaning and fumigating of all cleaners, dryers and stores is essential preparation for the valuable upcoming crop.

Harvest

Perfect weather conditions are rarely ideal and thus crops are often harvested over the desired moisture content of 14.5-15% maximum. Therefore, careful planning for the next steps is vital.

Post-Harvest

As trailers arrive with the newly harvested barley crop, the focus of the grain store operator is maintaining quality, in order to protect premiums and maximise margins.

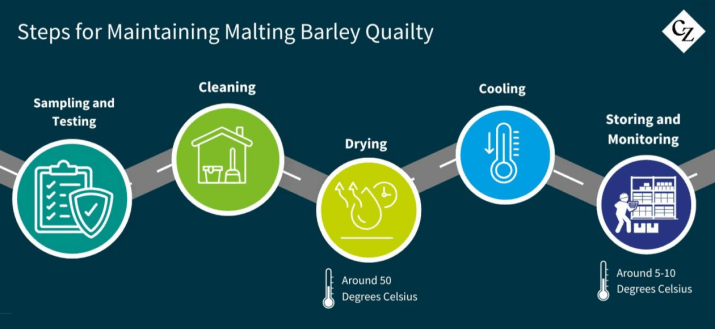

The main steps involve the following.

Sampling and testing

Obtaining samples and swift test results will clarify the quality of the crop. Multiple carefully collected samples from a heap is important to confirm whether the bulk is uniform or variable in quality across its entirety to enable any segregation if needed.

Testing will often be carried out by the buyer, who can equally assess grain colour and general suitability for the purpose for which the barley is intended. This can be of particular relevance in a difficult year when weather may have discoloured or resulted in any undesirable appearance of grains, which could be detrimental to its ultimate use and thus impact price.

Cleaning

As discussed in our Introduction to Malting Barley, cleaning is necessary to extract any chaff or admixture that may impair drying and storage, as well as helping meet the contract specification required.

Drying

Drying should be carried out with extreme care and as soon as possible post-harvest. This will help preserve germination and prevent moulds, mycotoxins and bug infestations, all of which are malting barley ‘demons’.

Due to the contractual need for a minimum 98% germination of grains, drying temperatures should not be too hot. This will depend upon type of dryer being used, but a rule of thumb is to keep dryer air temperature around 50 degrees Celsius so as to keep grain temperature at no more than 45 degrees Celsius.

This contrasts with feed grains, where dryer temperatures can be higher, (80-100 degrees Celsius) as quality criteria are much less stringent.

It is also worth noting that a lower temperature will slow down drying, which will be testing when time is of the essence in the midst of the busy harvest season.

Additionally, drying to a moisture level lower than ideal will not only increase time and costs but also reduce the weight, which directly impacts the amount the producer is paid.

Cooling

Once a clean and dry sample is achieved, the cooling phase should not be underestimated. Ambient temperatures in the heat of the summer can make this part of the process painfully challenging. Hot grains can quickly increase in moisture leading to a loss of germination, while increasing the probability of the above mentioned ‘demons’.

Cooling is accomplished by blowing cool, dry air over the grains as they finish drying and enter storage. Sounds simple, right? Not so much when ambient temperatures are 25-30 degrees Celsius during the height of summer! The air must be dry, as damp air would inevitably reintroduce moisture.

The cooling process can be extremely challenging, especially given its importance in sustaining a quality malting barley crop.

Storing and Monitoring

Finally, with an excellent quality malting barley crop safely in store, the farmer cannot afford to let his attention to detail slip.

Stagnation and the weather can play havoc with grain in store and the need to prevent an introduction of the malting barley ‘demons’ is critical.

Regular moisture and temperature checks should alert the seasoned storekeeper to potential problems ahead.

Ultimately, barley should be kept cold, at around 5-10 degrees Celsius for long-term storage, while moisture should be kept safely below 14.5%.

Post-Harvest Challenges

The challenges of growing a high-quality malting barley crop should not be underestimated. Nonetheless, preserving its value after harvest is equally challenging and just as important.

Store preparation, barley cleaning, drying, storing and monitoring all present their own tests for even the most experienced of storekeepers.

Any single failure in the process after the effort of growing and harvesting a high-quality malting barley crop can render it ‘unsuitable for the purpose for which it is intended’. A truly devastating financial blow, yet unfortunately, it’s all too often a reality!