What’s Happening on The Farm?

Hooray, the new sugarcane harvest has begun!

As the new crushing season began, I was interviewed by TV reporters.

I have now been growing sugarcane for eleven years, having started in 2012. A razor and a lighter are two small items that have been with me since I started farming, and they are also birthday gifts from my brother and son.

Life on the farm is comfortable now. In addition to sugar cane, there are fish, chickens and eggs, vegetable patches and fruit trees on the farm! This year, the tangerine trees did not bear many fruits, but the fruit size was not small!

At What Stage Is Your Crop?

The sugarcane is ripe for harvest. My little experiment continues: this is a plot where two different varieties of sugar cane are grown. One piece was planted with Guiliu 05136 and the other was planted with Guitang 42.

The Land of Guitang 42

The life cycle of Guiliu 05136 is five cuts, with an area of 83 mu* and a planting row spacing of 1.2 meters.

In 2020, the mid-cultivation was outsourced, resulting in serious excess fertilisation (223kg/mu!) Fortunately, in 2020, the weather was good, and the cane yields that year reached 8.1 tonnes/mu, creating a record!

My target this year is 5.5 tonnes/mu (82.5 tonnes/ha), which highly likely to be achieved. After the Chinese New Year, we plan to replant, with row spacing changed to 1.4 metres, and the variety will still be Guiliu 05136. Below, this variety is pictured.

It’s not easy to grow cane, and it’s even harder to harvest it!

After more than an hour of sampling, peeling cane husks, cutting fibrous roots, picking insect pests and selecting tail tips, the first sample actually contained 7.5% impurities, and the impurities of the second sample increased sharply to 16%. I decided to do a third sampling soon.

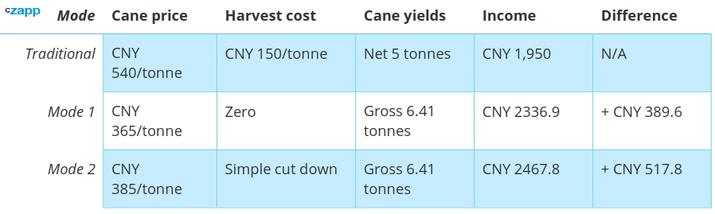

Guangxi has also introduced a new model of sugarcane purchasing with distributed machines that harvest sugarcane. The main difference is that farmers sell uncut cane directly, and cane leaves and tail tips account for about 22% of the gross weight, meaning farmers don’t need to cut cane. The processing service provider goes to the field to cut and transport the canes to sugar mills. In this way, the labour intensity is reduced for farmers and income is increased.

Under this model, farmers can earn an extra CNY 77.3/tonne (USD 10.8/tonne) of sugarcane.

If farmers are willing to cut down the sugarcane themselves, they can earn an extra CNY 103.5/tonne of sugarcane compared to the traditional model.

To me, this is a new model worth exploring.

What Big Concerns Do You Have Now?

It’s more accurate to say that we’re aiming rather than worrying.

From 2016 to 2023, our planting row spacing has gradually changed from the 1.80-metre wide and narrow double row that prevails in large foreign farms to the 1.40-metre single row suitable for China’s land conditions.

The sugarcane harvester has also gradually changed from a large-scale combine harvester of a world-renowned brand to a domestic small and medium-sized harvester. The whole process of mechanized production of sugarcane has a long way to go!

Technology is constantly bringing convenience to our farmers but sometimes there are sweet annoyances too. Especially if you forget to charge your drone.

Even with this screenshot and familiarity with my surroundings, I had to drill into the lodging cane field for more than half an hour, emerging with cuts all over my arms, and I only brought this little thing back.