Introduction

As a versatile material, glass has been used by humans for thousands of years. The first man-made glass was created about 4,000 years ago in Mesopotamia, when craftsmen discovered the art of mixing sand, soda and lime to make glass.

Early manufacturing efforts looked very different than they do today. Glassmakers would heat the sand, soda and lime mix in open moulds or would use core forming techniques to create hollow glass items. At this time, glass was reserved exclusively for the upper classes and was used mainly for decoration or to hold perfumes or oils.

From everyday objects like windows and bottles to intricate works of art, glass has now become an integral part of our lives. As the discovery spread across Mesopotamia to the Mediterranean and central Europe, manufacturing techniques evolved and today, the world produces an estimated 130 million tonnes of glass each year.

Why Glass Is Important in Packaging

Glass has many beneficial properties which makes it a very advantageous product in the packaging industry:

1. Non-reactive and Impermeable

Glass is inert. This makes it a safe option for packaging, especially for sensitive products, and ensures the quality and taste is protected and maintained for longer durations.

2. Recyclability, Reusability and Sustainability

Another great attribute of glass is the fact that it’s 100% recyclable and often can be reused for various purposes (e.g. DIY projects, storage, etc.) making it versatile for consumers.

3. Branding

Glass has a visual appeal due to its transparent characteristic, allowing for consumers to see the contents.

4. Cheap and Versatile

Glass is inexpensive to make and there’s the flexibility of being able to form glass into different shapes and sizes, making it very versatile.

5. Resistance to Heat and UV Light

Glass is heat resistant so it’s suitable for beverages and food that go through sterilization and pasteurization, as it does not release harmful substances when placed under heat. Also, glass possesses properties that make it excellent at UV light-blocking. This protects light-sensitive products like beverages from degradation caused by exposure to sunlight, extending shelf life and maintaining the efficacy of the packaged goods.

The Making of Glass

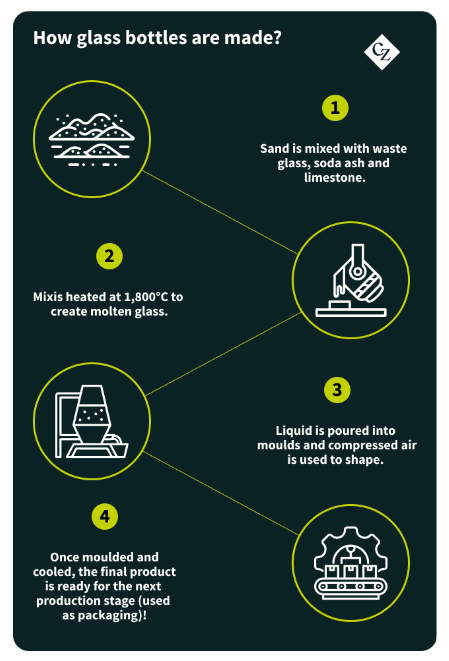

Glass is made of opaque sand, despite it being completely transparent as an end product. Nowadays, ordinary sand, which is made up of mostly silicon dioxide, is mixed with waste glass, soda ash (sodium carbonate) and limestone (calcium carbonate) and is heated at 1,800°C to create molten glass. The soda reduces the sand’s melting point, which helps save energy during manufacturing. The limestone ensures water-soluble sodium silicates don’t form during the process. The ordinary glass material produced as an end-product is called soda-lime-silica glass.

Depending on the desired end-product and application, glass can be made using different techniques: blowing, pressing and drawing. Glass for the food and beverage industry is made through two techniques:

Press and blow: This is the most commonly used method for food and beverage bottles. Sections of molten glass are dropped into moulds within an individual section machine. The molten glass is then pressed into the mould to take shape. The glass shape then becomes what is known as a “parison,” which is reheated again to soften it. Compressed air is then blown into the mould to shape the glass into bottles, containers or any other packaging.

Blow and blow: This process is best suited to narrow necked containers. It also uses moulds and an individual section machine, but this time compressed air is used to form the initial parison. It is then flipped, reheated to soften and more compressed air forms the final glass shape.

After the glass bottles have been formed, they must be annealed to remove stress and strengthen them. A special type of furnace called a lehr is used. The process is highly scientific and varies depending on the design and shape of each product. However, it is important to ensure that the inside and outside of the product cools at the same rate.

After the glass is inspected to ensure quality, the products are ready for packaging and shipping.

Types of Glass

Nowadays, glass bottles come in countless shapes, sizes and shades. Some even have different properties according to their purpose. The three main types of food-grade bottles are soda-lime, treated soda-lime and borosilicate but glass can also be made with leaded or crystal glass, which contain chemicals such as lead oxide, zinc oxide and potassium oxide. These glass bottles are decorative due to the chemicals used.

Soda-Lime/Soda-Lime-Silica: The most common type of glass bottle is also known as a Type III bottle. It is made with 75% silica, 15% sodium oxide, 10% calcium oxide and small amounts of magnesium, potassium, and aluminium oxides. Each ingredient provides different properties that create an extremely versatile type of glass. These are the most commonly used bottles in food and beverage packaging and the glass can be tinted amber to protect contents from UV light.

Treated Soda-Lime: Treated soda-lime glass bottles, or Type II bottles, are very similar to Type III glass bottles. The biggest difference between the two is that Type II bottles are treated inside with sulphur. Type II bottles also have a lower melting point than Type I bottles, making them easier to mould. However, this means it cannot withstand hot environments as well. These bottles are most commonly used in medicine, particularly to hold injectable medications.

Borosilicate: This kind of glass bottle is made from 80% silica and 10% boric acid. The remaining 10% consists of sodium oxide and aluminium oxide. These bottles are 10 times stronger than Type II bottles and are often used for laboratory chemicals. This is the glass that Pyrex branded products are made from.

Recycling Glass

Glass is completely recyclable, meaning it is highly sustainable. While other recycled items can lose quality during the process, glass can be recycled infinitely. The raw ingredients used to make glass – sand, limestone and soda ash – have to be mined using CO2 intensive processes. This means that every time a glass bottle is recycled, a huge amount of CO2 emissions is saved.

For every tonne of recycled glass, 580kg of CO2 is saved, air pollution is cut by 20% and water pollution by 50%.

Glass is recycled by being melted back to its molten form and remoulded. It may need to be sorted by colour first. It can also be reinforced with new properties during the process by mixing it with raw materials.

Because of the ease of recycling, glass has a much higher recycling rate than many other forms of packaging. In Europe, the recycling rate is above 75%, compared with 40% for plastic and 30% for wood.

Who’s Who in Glass Packaging

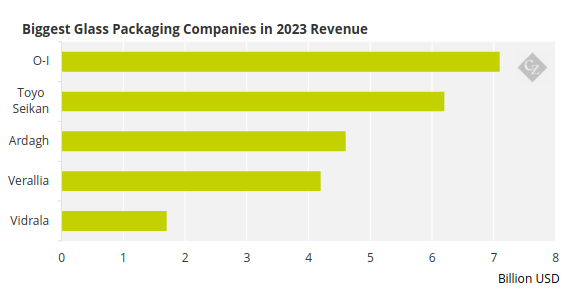

There are several companies that specialise in glass packaging but some, such as Ardagh and Toyo Seikan, also produce metal, paper and plastic containers.

Glass bottles are most commonly used for storing wine, spirits, beer, juices, sodas and sauces. This means that some of the biggest sellers of goods sold in glass jars include:

- Anheuser-Busch InBev

- The Coca-Cola Company

- PepsiCo

- Diageo

- Suntory Holdings

- Kirin Holdings

- Pernod Ricard

- Molson Coors Beverage Company

- Constellation Brands

- E&J Gallo Winery

Exporters and Importers of Glass

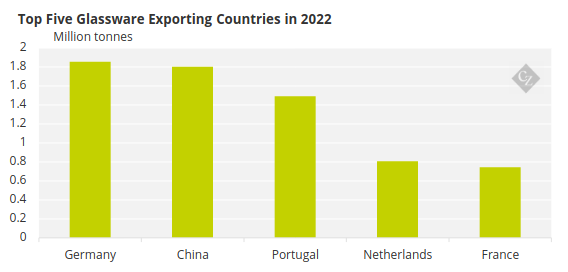

In 2022, about 41.4 million tonnes of glass were exported around the world.

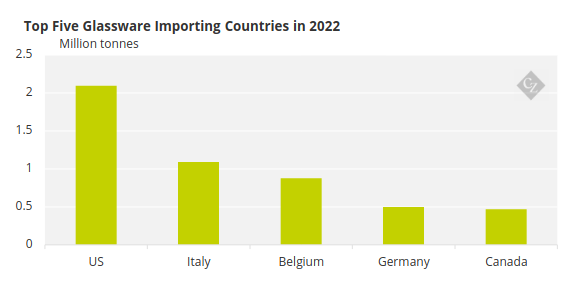

The top five glassware exporters in 2022 were Germany, China, Portugal, the Netherlands and France. Their exports totalled around 6.7 million tonnes of glass packaging – or 44% of total glass exports.

While most of Germany’s glass packaging exports are intra-European, much of China’s exports go to the US. Of the roughly 1.8 million tonnes of glassware exported by China in 2022, about 18% was sent to the US.

It is little surprise that glass packaging imports are focused on Europe and the Americas. According to a ranking by BarthHaas, a German hops trader, the top five beer producers in the world are China, the US, Brazil, Mexico and Germany. China is not a glass packaging importer since it is a major producer.

Where Does Glass Come From?

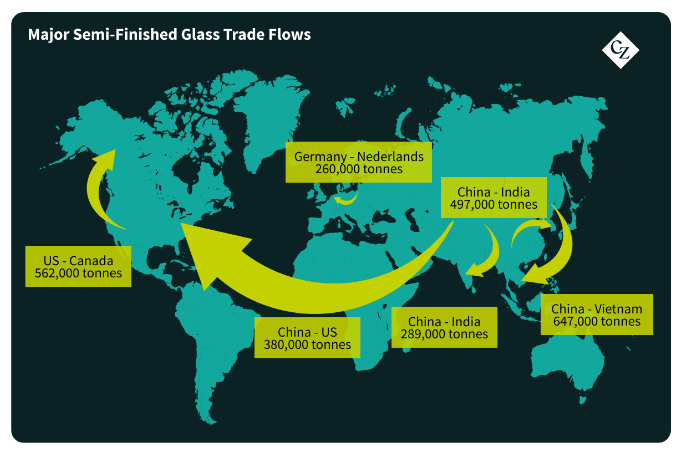

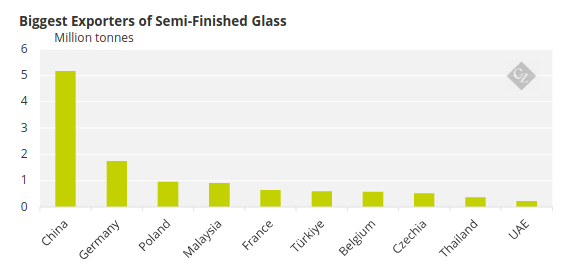

China is not only one of the biggest glass packaging exporters, but it also exports a huge amount of the semi-finished glass products required to make packaging.

In fact, it is the biggest exporter of semi-finished glass materials, followed by Germany, Poland and Malaysia.

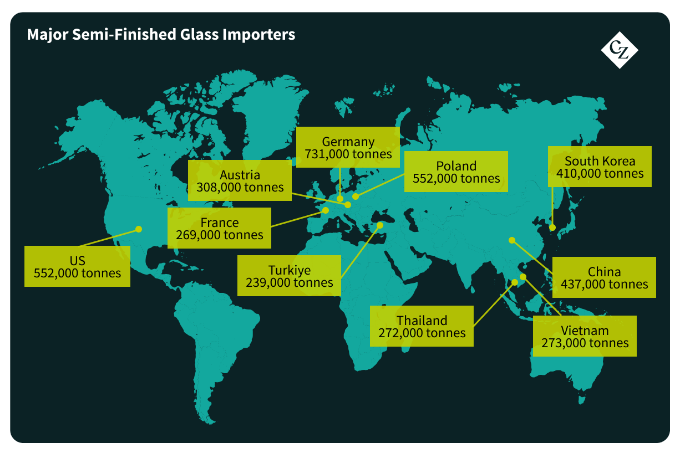

European countries import a significant amount of semi-finished glass. From there, it is shaped into glass packaging and sold within the EU or exported. The US is also a large importer of semi-finished glass products.

Future Outlook

Innovation in Glass Packaging

As trade becomes more global, glass packaging is becoming more and more lightweight. Due to its weight, glass packaging is traditionally less sustainable to transport. However, since 2010, the typical weight of a glass container has been reduced by about 40% as companies embark on “lightweighting” initiatives. The challenge is ensuring the bottle’s properties remain the same while reducing weight.

Ardagh produces the world’s lightest beer bottle, which weighs 155g for 330ml. It has also designed a 70cl spirit bottle and a 700ml wine bottle that weighs less than 300g.

Another innovation being explored by O-I is the 3D printing of glass packaging. This process will allow companies to create bottles in virtually any shape they want. O-I currently offers this service to clients on a custom basis.

Glass Packaging Challenges

While glass is one of the most highly recycled packaging materials, in some parts of the world, recycling rates are extremely low. In the US for instance, only about a third of all waste glass is recycled. Europe has a good reputation for recycling glass, led by countries such as Germany and Spain. But Romania has one of the lowest glass recycling rates in Europe at just 13%.

And because glass production is highly energy intensive, when energy prices rise, glass production becomes less profitable. The production of glass is also highly dependent on raw materials, the flow of which have been disrupted by challenges in global supply chains.

Conclusion

- Glass is made of opaque sand, despite it being completely transparent as an end product.

- Depending on the desired end-product and application, glass can be made using different techniques: blowing, pressing, and drawing.

- Glass has many beneficial properties that make it a very advantageous product in the packaging industry.

- In 2022, 41.4 million tonnes of glass bottles were traded globally.

- There is a great deal of intra-EU trade, but also trans-Atlantic and trans-Pacific flows.

If you have any questions or are interested in the glass market, get in contact with our FIP team here: