Insight Focus

ME Energy’s Rapid Charger 150 drives sustainable innovation. This technology generates electricity from low-cost ethanol, providing a grid-independent charging solution. It has the potential to significantly increase corn demand while supporting the shift to electric vehicles.

Driving Innovation in Sustainable Corn

Winners of the Radicle Corn Value Chain Challenge contest have developed the Rapid Charger 150, a unique technology that generates climate-friendly electricity from low-cost ethanol. These portable rapid chargers, powered by renewable energy such as corn bioethanol, do not require a connection to the power grid as they generate their own electricity.

The innovation was developed by Germany’s ME Energy, which took home the USD 1 million first prize at the competition. ME Energy’s innovation not only provides a sustainable charging solution but also creates a new use for corn. The company stated that this new charging technology could increase demand for corn by as much as 1.1 billion bushels, equating to 3.2 billion gallons of ethanol.

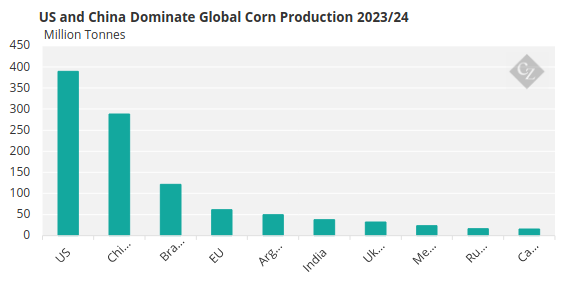

Source: USDA

The standard Rapid Charger 150 unit contains 2,000 litres (550 gallons) of ethanol when full and supports more than 100 charges. Typically, the ethanol supply is topped up every one to two weeks, depending on usage patterns.

The buyers are those making the transition towards electric vehicles and away from combustion engines, though combustion is the means by which ethanol is converted to power.

The company said the chargers are a counterweight to the reduction in ethanol demand that may come from the EV transition.

Who Will Use the Charger?

Users of the Rapid Charger 150 could include emergency service organisations that rely on round-the-clock vehicle availability, such as hospitals, fire departments and police fleets. Additionally, fleet owners who require resilient or remote charging solutions in situations where the power grid is down could find the technology useful.

Furthermore, fleet operators looking for cost-effective fast-charging options to enhance vehicle uptime, such as bus and trucking fleets, would benefit from this technology.

Other Winners

The challenge’s second prize of USD 500,000 went to US-based Lakril Technologies. Lakril’s bifunctional catalyst enables the efficient conversion of corn ethanol into bio-based acrylics, offering a sustainable alternative to traditional petrochemical methods.

Other finalists were Catalyxx and New Iridium. Catalyxx has a unique, proven and patented green chemistry technology that produces high-value long-chain linear alcohols from corn ethanol that serve as intermediate biochemicals to decarbonise the downstream chemical value chain.

New Iridium’s photocatalysis platform empowers the production of low-cost sustainable chemicals, such as acetic acid, from plants and carbon dioxide. While the acetic acid value chain is currently reliant on petroleum, innovations like photocatalysis could enable sustainable production from corn ethanol.

In total, 132 companies competed in the challenge, with 41% of them from outside the US.