Insight Focus

New tech will help ethanol producers maximize byproduct value. Distillers Corn Oil (DCO) has benefited from these advancements, with improved yields and efficiency. Fluid Quip Technologies (FQT) has helped plants like Ace Ethanol recover higher oil yields, enhancing profitability.

New technological developments are helping ethanol producers squeeze more value from their byproducts. One such byproduct receiving a recent boost from new technology is Distillers Corn Oil (DCO), a key ingredient in swine and poultry feed.

Fluid Quip Technologies (FQT), an Iowa-based technology and engineering supplier to the ethanol industry, recently announced that it had helped Wisconsin-based Ace Ethanol achieve improved results using FQT’s DCO technology. After 12 months of operation at Ace, the DCO technology helped recover an average of over 1.3 lbs/bushel of corn.

What is DCO?

Distillers Corn Oil, or DCO, is primarily used as a high-energy source in poultry and swine diets due to its high metabolizable energy (ME) content and relatively low cost compared to other feed fats and oils.

According to the US Grains Council, the market price of DCO is closely linked to the price of yellow grease in the US fats and oils market. However, DCO contains substantially greater ME content than yellow grease and has a comparable ME content to soybean oil.

According to FQT, their DCO technology directs more oil to the thin stillage stream, increasing yields, while also removing solids from the evaporator to enhance energy efficiency. A key feature of the DCO technology is its ability to recover additional oil without relying on increased chemical or enzyme solutions, enabling plants to achieve higher yields without a rise in long-term operational expenses.

“The DCO system has continued to achieve record oil yields for Ace. We saw increased oil out of the gate and the system has continued to show impressive recovery over the long-term without additional spend on chemicals, which has added more income to our bottom line,” said Neal Kemmet, President of Ace Ethanol.

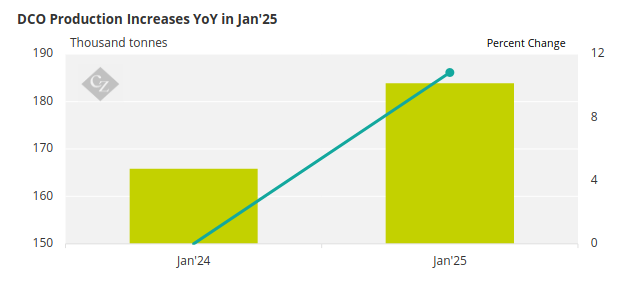

Source: RFA

ICM, a Kansas-based biorefinery technology provider, recently highlighted that since DCO became a high-value coproduct in the ethanol industry, both producers and technology providers have worked to maximise the amount of DCO they could recover.

Initially, DCO yields above 0.5 lbs/bushel were considered acceptable, and within a few years, 0.75 lbs/bushel became a sustainable target. Over time, yield trends crept higher, with whispers and rumours of some producers achieving DCO yields of 1 lbs/bushel or higher.

However, recent press releases have been much louder than whispers, with numbers significantly higher than 1 lbs/bushel, surpassing previous industry standards, ICM said. Ethanol producers are experiencing breakthroughs, thanks to new technologies and an evolved focus on whole-plant optimization.

New Tech Improves Performance at São Martinho Plant

In another recent announcement from FQT, the company stated that the São Martinho Boa Vista distillery in Quirinópolis, Goiás, Brazil, is exceeding projected performance in both capacity and ethanol output.

The São Martinho plant utilizes FQT’s proprietary corn ethanol technologies, ranging from corn receiving to DDGS drying, after integrating its Low Energy Distillation (LED)™ system and a Mechanical Vapor Recompression (MVR) system. This has enabled the plant to achieve one of the lowest steam usage rates in the bioethanol industry while utilising low-pressure steam from the São Martinho cogeneration turbines.

“São Martinho saw the need for a low pressure and low energy distillation system allowing for a substantial reduction in energy usage, due to limitations on steam generation capacity and biomass availability,” said FQT executive vice president John Kwik.

“This was a first of a kind distillation system operating at 1.5 bar making anhydrous ethanol, so we worked together to make the necessary adjustments that allowed the FQT engineering team to achieve the goals of maximising ethanol and corn oil yields and substantially reducing energy usage,” Kwik said, adding that this is a real technology disruptor for the South American ethanol market.

São Martinho is a high-performing plant that makes ethanol from both sugarcane and corn. The facility produces approximately 200 million litres of ethanol per year from corn.