Insight Focus

- Coca-Cola launches 100% rPET bottles in India and Indonesia, boosting regional recycling.

- North American governments target changing to recycling labels.

- LanzaTech and Plastipak produce PET resin from greenhouse gas emissions.

This Month’s Top Trends

1. Coca-Cola Indonesia and Coca-Cola India

Coca-Cola Indonesia and Coca-Cola India are taking significant steps towards incorporating recycled plastic into their packaging, in line with Coca-Cola’s global goal of using at least 50% recycled material in all packaging by 2030.

In Indonesia, Coca-Cola, in partnership with Coca-Cola Europacific Partners (CCEP), has launched bottles made from 100% recycled PET (rPET) plastic. This development brings rPET packaging to popular Coca-Cola brands such as Fanta, Sprite, and Sprite Waterlymon in Indonesia for the first time.

CCEP and Dynapack Asia have also established a state-of-the-art recycling facility in West Java, to manufacture these recycled bottles.

In India, Coca-Cola, in collaboration with ALPLA, has also achieved a significant milestone by introducing a bottle made from 100% rPET in Andhra Pradesh. This marks the first time in India that a 100% rPET bottle has been used for food or drinks.

The bottle, launched under the Kinley brand, is entirely made from recycled food-grade plastic, emphasizing their commitment to a circular economy. This initiative aligns with India’s sustainable plastic use vision and the government’s “Swachh Bharat Mission” (Clean India Mission).

Coca-Cola India and Zepto have also joined forces to launch their “Return and Recycle” initiative.

Initially launched as a pilot project in Mumbai, the collaboration establishes an effective process for collecting PET bottles with 100% traceability to ensure proper plastic waste management.

The pilot project received an overwhelming response, with over 100 kg of PET bottles collected and recycled within 60 days.

The collaboration aims to digitize the collection strategy using e-commerce platforms, making the process more efficient and raising consumer awareness of sustainable collection models. Collection bins will also be deployed across Zepto delivery hubs in major cities.

Zepto’s potential, and that of other delivery services, to boost India’s circular economy had been previously reported here.

2. Recycling Labels Face Changes Amid Greenwashing Concerns

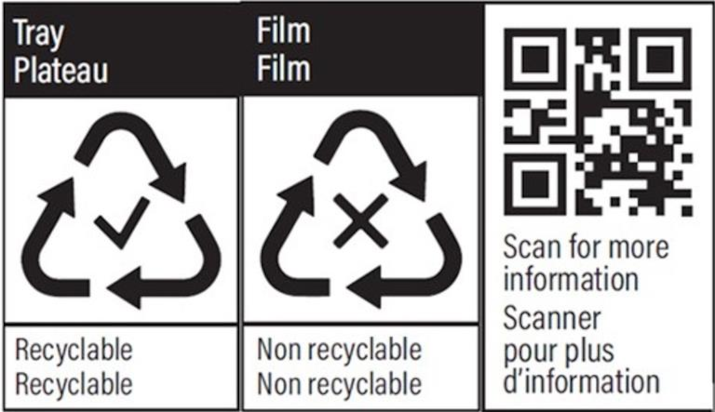

The governments of Canada, the United States, and Australia are taking steps to address consumer concerns over greenwashing and promote the use of recycled plastics in packaging.

Canada is proposing mandates for 30-60% recycled content in plastic packaging by 2030 and an 80% threshold for products to be marketed as recyclable. They also aim to collect 90% of plastic packaging and recycle 65% of it after accounting for yield loss.

Canada’s plan also includes a three-tier system for using the “chasing arrows” symbol and resin identification codes and proposes varying requirements for flexible packaging based on material thickness.

Similarly, in the United States, the EPA and state agencies are working on stricter guidelines for green marketing, particularly regarding the chasing arrows symbol.

The EPA recently stated that resin codes and chasing arrows “does not accurately represent recyclability as many plastics (especially 3-7) do not have end markets and are not financially viable to recycle.”

3. Carbon-Neutral Plastics?

LanzaTech and Plastipak have successfully produced PET resin using carbon captured from greenhouse gas emissions.

The PET resin, called PPKNatura, is made using LanzaTech’s captured carbon emission-based monoethylene glycol (MEG).

LanzaTech’s technology can convert carbon emissions into MEG through fermentation, eliminating the need for an ethanol intermediate.

This innovative process allows for the production of low-carbon, virgin-quality PET resin suitable for various packaging applications, including food and pharmaceutical grade packaging.

The partnership between LanzaTech and Plastipak aims to demonstrate the potential for reducing carbon footprints in the packaging industry. By utilizing carbon captured from emissions, they are able to create PET resin with a lower environmental impact compared to traditional production methods.

The fact that Swiss retailer Migros and its subsidiary Mibelle Group have already adopted this PET resin in their packaging further emphasizes the viability and acceptance of this innovative solution.