Insights Focus

Raízen is partnering global companies to produce SAF in Brazil. Production could start from 2027. Sustainable aviation fuel should boost the ethanol industry.

Brazil should produce SAF from 2027

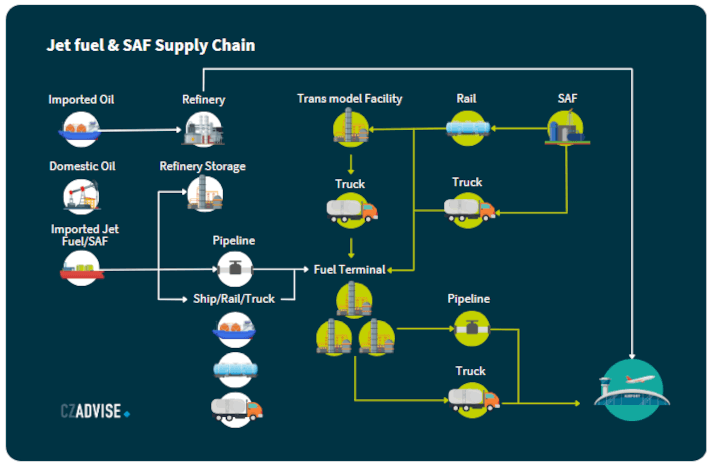

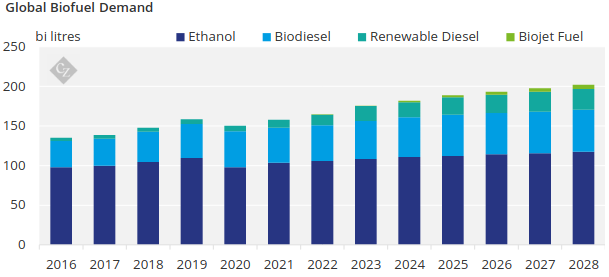

Sustainable aviation fuel (SAF) is currently the only viable way to decarbonize air travel. Brazil is the world’s second largest ethanol producer, and ethanol can be used to make SAF through the alcohol-to-jet pathway. This puts Brazil in prime position to become a major SAF producer.

Raízen intends to take the lead, through agreements for the development of SAF with international partners. They expect SAF production in Brazil to begin in the next three years. “We are going to convert Brazilian energy generation capacity into products to meet decarbonization goals”, says Paulo Côrte-Real Neves, VP of Trading at Raízen, in an interview with CZ app.

Paulo Côrte-Real Neves, VP of Trading Raízen. Source: Raízen.

How is the search for partners to implement Raízen’s SAF plant in Brazil?

We have worked hard to promote and help our partners around the world who are interested in developing the conversion of ethanol to aviation fuel, alcohol-to-jet (ATJ). Brazil does not have this technology. But some companies in the world are advancing in their development and we have worked with them to support these advances.

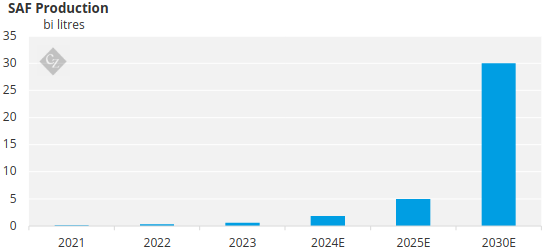

The aviation industry’s objective is to reach more than 25 million cubic meters of SAF by 2030 and 25% of the total should come from ethanol. So, this is a new market with very interesting potential.

How is the research to develop SAF in Brazil going?

We are working with global partners to develop SAF production here. There are working groups with different partners to seek this solution. The SAF produced in Brazil should have a smaller carbon footprint due to our energy matrix being renewable, which is an attractive feature.

How soon will Brazil be able to start producing SAF?

It’s difficult to talk about this because there is uncertainty about the technology maturity process. But we expect that this year or in 2025 this technology can evolve towards larger-scale production. When overcoming the technological barrier, a business of this nature can take two to three years to be ready. So, we are talking about 2027.

It’s not that far, is it??

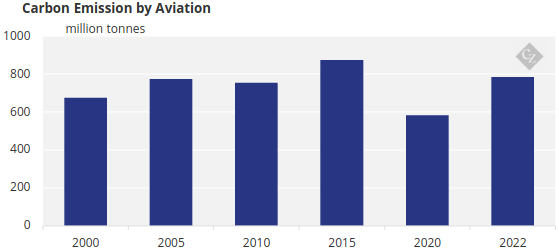

No. And the world needs SAF. Airlines and the different players in this industry need a decarbonization solution. New solutions need to be developed to meet the 2030 decarbonization objectives and alcohol-to-jet seems to be very suitable. Today, aviation is responsible for around 3% of carbon emissions in the world and until recently there was no solution for decarbonization.

Source: IEA.

Today, the cost of SAF is three to four times that of conventional jet fuel. Is it a challenge?

Yes. This factor is the result of the current stage of technological development. Certainly, over the next few years we will see this industry evolving. Costs will decrease. As technology evolves and gains scale, it will be in a position to promote a competitive solution and increase production.

Source: IATA.

Will second generation ethanol also be more competitive?

Undoubtedly. We have two plants and are building two others that should be ready this year. Two other units are expected to open next year. We are replicating the plant that has existed for ten years, but obviously there is a series of lessons learned that we have been implementing. This reduces costs and will also have a positive impact on SAF production.

After the first ten-year cycle, when the investment is repaid, the production cost of second-generation ethanol becomes lower than that of the first generation, especially because it is made from sugarcane residue.

Raízen has also been dedicated to developing ethanol to be used as ship fuel. What stage is this technology at?

This market should have a very relevant scale, similar to that of SAF. The maritime industry consumes around 140 million cubic meters of fuel per year. So, for every 1% of biofuel added, this already adds up to 1.4 million cubic meters.

Last year we signed a collaboration agreement with one of the largest shipbuilders in the world, a Finnish company, Wartsila. We are in the testing phase to prove that the engines can use ethanol and methanol. And as fleets are renewed, they will be able to be built with these engines. Technology already exists. It is being proven now and we are very optimistic.

Source: IEA.

This should open up a large market for ethanol?

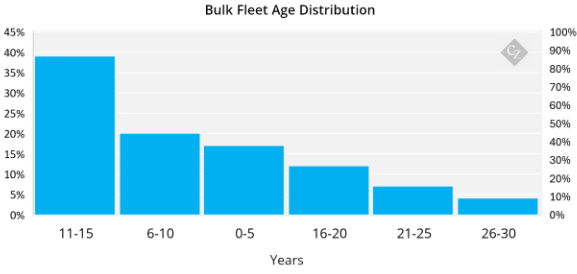

Undoubtedly. It’s a huge market that we hope to explore. Of course, there is time for fleet renewal to happen. Each ship lasts an average of 20 or 25 years. But the fleet has not been renewed in recent years precisely because shipowners are uncertain, as existing engines today have no decarbonization alternative.

Source: AXS.

As they are building ships that will be in operation for 25 years, they know they will not be able to use the current engine. So, there is a pent-up demand for shipbuilding.

Brazil today is a global leader in renewable energy production. Our journey at Raízen is to convert energy generation capacity into internationally recognized products to meet decarbonization goals.