- The recycling industry is witnessing a post-COVID investment boom as companies compete for future supply.

- Multiple investments were announced in August across Asia and the US.

- Will the PET industry see a wave of future consolidation with some producers unable to move towards RPET?

Post-COVID Investment Boom in Recycling

The recycling industry has faced many challenges over the last 18 months, from disrupted collection systems and labour shortages, to increased competition from low-priced virgin plastics.

Despite the difficult business environment, multinational brands have shown an unwavering commitment to sustainability targets. As the world now emerges from the current pandemic, the plastics industry is experiencing a post-COVID investment boom into its recycling sector.

Major Virgin Plastics Producers Target a Rapid Transition

Over the last few months, several major virgin plastics producers have announced large new investments into the recycling space as they seek to transition towards recycled PET (RPET).

Within the US market, CarbonLite Recycling’s bankruptcy and subsequent asset auction provided an opportunity for both Indorama Ventures and Alpek, the two largest producers of virgin PET resin globally, to significantly increase their share of installed RPET capacity within the country.

Both Indorama Ventures (IVL) and Alpek have rapidly expanded recycling capacities in recent years through the targeted acquisition of large, efficient, and economically viable, recycling plants.

IVL has committed $1.5 billion to recycle 50 billion PET bottles into 750k tonnes of RPET annually by 2025, which will total 25% of the company’s production in North America and Europe. IVL has now built, acquired, and integrated 13 recycling businesses globally over the last decade.

Whilst Alpek’s acquisition of Carbonlite’s facility in Reading, Pennsylvania in the United States, brings the company’s installed rPET capacity to 394k tonnes and reaffirms Alpek as the largest PET recycler in the Americas.

Within India, Reliance, India’s largest private sector company and largest exporter, is also seeking to double down on its transformation towards a sustainable future.

Reliance has committed to more than doubling its recycling capacity within India to around 5 billion post-consumer PET bottles, a move that will bolster the company’s footprint within India’s recycled polyester staple fibre market.

Institutional Investors Supporting Green Deals

With social and political pressures surrounding the use of virgin plastics, there is a growing clamour amongst the financial investor community for sustainable ‘green deals’. With such a favourable investment environment, new recycling ventures aren’t the sole preserve of major plastics producers with the month of August witnessing several key announcements, including:

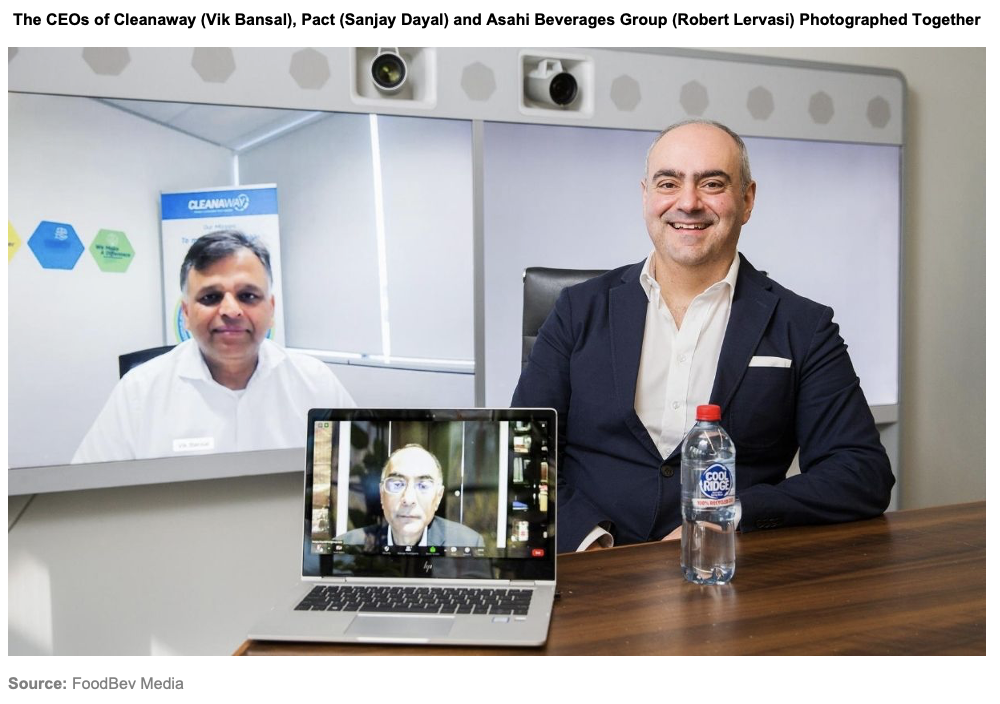

· Pact Group, Cleanaway, Asahi Beverages and Coca-Cola Europacific Partners (CCEP) plan to develop a new 20k tonne PET recycling facility in Australia. Although the precise location is yet to be confirmed, they’re aiming to complete construction by 2023. The four companies are currently building another PET recycling facility in Albury-Wodonga, Australia, through Circular Plastics Australia (PET).

- The American Beverage Association and the Ohio Beverage Association, in partnership with Closed Loop Partners, a New York-based investment firm, announced a $5 million investment toward Evergreen’s $22 million expansion of PET recycling plant in Clyde, Ohio.

- Earlier this year, Evergreen announced its plans to double production capacity at its plant to 80m pounds (around 36k tonnes) of RPET by 2022.

- Within Asia, Dialog, a Malaysian oil and gas services company, outlined plans to build a new $25 million food-grade recycled polyethylene terephthalate (RPET) pellets production facility within the country.

The newly established Plastics Recycling Association of Singapore is also studying a proposal for the country’s first bottle-to-bottle recycling plant. If successful, the hope is to build a plant capable of handling around 150 million plastic bottles a year, equivalent to 30% of the 500 million PET plastic bottles discarded annually in Singapore.

PET: The Pathfinder for Other Recyclable Plastics

Success within recycled PET has also forged the way for gains within the wider plastics recycling industry, including several recent projects aimed at tacking other packaging materials.

In August, PureCycle Technologies announced plans to build a $440 million recycling plant in Augusta, Florida. Construction on the company’s other ‘flagship’ Ironton Ohio site is also currently underway and, according to the company’s latest financial report, the plant should begin commercial production by the end of 2022.

PureCycle’s recycling process was developed by Procter & Gamble and transforms polypropylene (PP) waste into an “ultra-pure” recycled PP resin.

According to PureCycle, the company has already presold more than 20 years of output from the Ohio plant and has already allocated 40% of its second plant in Augusta to customers.

Within the last month, Purecycle has also signed MOUs with Mitsui & Co., and separately SK Chemicals, for PP recycling plants in Japan and South Korea.

Whilst, in Australia, the Pact Group and Cleanaway announced a $38 million investment in what would be Australia’s largest post-consumer polyethylene recycling plant at Laverton, Victoria.

Concluding Thoughts

As the world enters a period of post-pandemic growth, many major PET producers have not only ridden out the storm but been able to post strong financial performances over the last 12 months.

With demand for plastics and packaging set to experience robust growth in 2022, lifted by a post-COVID global recovery, a new wave of acquisitions and investment within the recycling space may be on the cards.

Traditional virgin producers will continue to seek rapid expansion within rPET to secure future supply chains as the world transitions towards recycle. The US recycling sector will continue to be ripe picking for acquisitions and investment opportunities.

However, whilst some can expand rPET capacities rapidly, those virgin producers that aren’t able to get a slice of the recycling pie face being left out in the cold upon future minimum content regulations, potentially ushering in a new wave of closures and consolidation.

Other Opinions You Might Be Interested In…

- RPET Trends in September 2021

- RPET Trends: Recycling’s Digital Revolution

Explainers You Might Be Interested In…