So far, our discussion on fertilizer has centred around the use of synthetic fertilizer. For the next two reports, we’ll shift our focus onto two alternative sources of nutrients: manure and biosolids.

Although these alternatives share some similarities with synthetics (particularly in terms of amounts, placement and timing), they also have significant differences, especially in regard to their environmental profiles.

In this report, we’ll primarily be considering the use of animal manure on arable crops (except rice). Issues surrounding production, storage, human safety (and more) will be discussed in future articles, along with the use of green manures and compost.

Using Manure in Sustainable (Intensive) Agriculture

Manure has been used as a fertilizer for at least 8000 years. Although there’s no current evidence that the ancient Mesopotamian Hearth used it, early Europeans certainly did. Responsible use of manure is compatible with Sustainable (Intensive) Agriculture.

In the underdeveloped world, it can sometimes be the only affordable or available source of plant nutrients, which play a key role in improving food security and human welfare. There is, however, a danger of over applying nutrients, as these materials are not always tested for nutrient content.

In the developed world, increased livestock populations have created difficulties with manure disposal, but used properly, it still provides a valuable nutritional resource.

Manure Application Systems

Soil amendments are any material that’s applied to the soil to enhance plant growth. In this context, manures (as an amendment) are a member of the ‘soil conditioner’ sub-group.

They are available to the farmer in two forms: Farm Yard Manure (FYM) and liquid manure (slurry), derived from more intensive livestock operations. They have a dual role of adding nutrients to the soil but also improving soil organic matter, water retention on dry soils and adjusting pH levels. Synthetic fertilizers only achieve the addition of nutrients. Manure soil conditioners are essentially using a by-product that’s difficult to dispose of in an environmentally responsible way by other means.

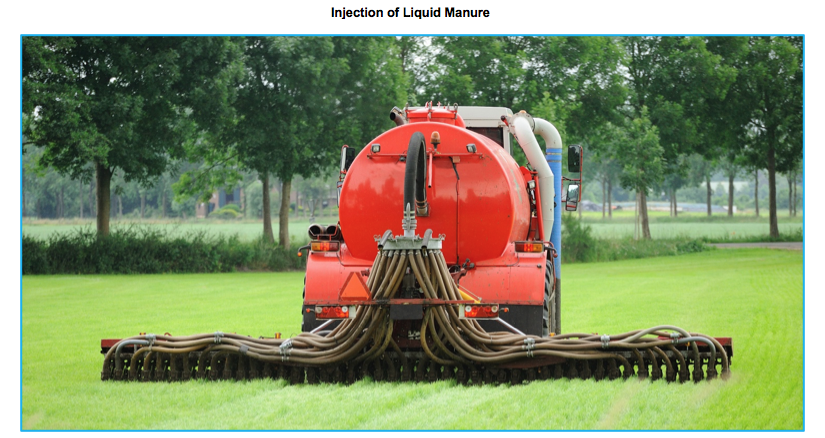

FYM is normally applied using a tractor pulled trailer, while slurry is applied using an in-field tank system. Although improvements are needed in FYM application techniques, the more challenging area is slurry.

Traditional slurry application systems use a broadcast spreader, with the slurry being forced through a nozzle onto the field; it’s distributed with a splash plate as a thin film across the entire spreading width of the machine.

Although there’s the benefit of no greenhouse gas emissions (from a fertilizer factory), this is an inferior system for SA and SIA. This is because, in some circumstances, loss of nutrient is up to 80% of the available N, and more than 20% is often lost as ammonia (NH3) in the first hour. Ammonia is not a greenhouse gas, but it does cause atmospheric pollution.

Some minor improvements can be made with a swivel spout applicator instead of a splash plate, but it’s not really a solution.

Splash plate systems are under increasing scrutiny and are already banned in Holland and Germany, with the UK government proposing their ban from 2025. This is hardly surprising as nearly 90% of the UK’s NH3 emissions come from agriculture and almost all UK farmers are still using splash plates…

Some more suitable alternatives include:

1. Band Spreaders. These apply the slurry through evenly spaced flexible pipes. This reduces the slurry’s exposure to the air and enables a more accurate spread pattern. It’s most effective on crops that are mature enough to cope with any risk of scorch. You can also apply slurry with this method to crop stubbles and bare soil, but the benefits are reduced and runoff risks increase.

2. Trailing Shoe. This system is mostly used on grassland but can be adapted for arable row crop use. The ‘shoes’ place the slurry in discreet bands, which is always an improvement over blanket applications. NH3 emissions can be halved with both Band Spreaders and Trailing Shoe methods.

3. Shallow and Deep Slurry Injection Systems. These use disc cut slots for the injection and are therefore consistent with minimal soil disturbance and SA/SIA principles. The two methods can cut NH3 emissions by up to 70%, especially when used on a growing crop. Shallow injection systems are the preferred method for arable crops.

These three methods can all be adapted for use in Variable Rate Technology (VRT) systems.

There are several other issues to be discussed with slurry applications, though. Trailing Shoe and Injection systems are more complicated and work at slower speeds; this makes them more expensive. As slurry applicators are not a key piece of machinery for an arable farm, hiring of a contractor is worth considering.

In all systems, tanks are heavy and care has to be taken to avoid excessive soil compaction. One suitable method is to use an ‘umbilical cord’, which pumps the slurry from a tanker or storage facility away from the field.

One unpleasant side effect of slurry/FYM application systems is the odour. The pungent smell of pig slurry in a field on a warm day can be overwhelming. There are several remediation methods, all relating to good livestock management practices. Some of these remedies are cheap (better use of covers), whilst others are more costly (introducing ozone).

Once these materials have arrived at the field, little can be done for FYM, although common sense on ambient temperature and wind speed and direction are advised. The injection systems described for slurry can certainly help.

Nutrient Benefits

The plant nutrition and soil improvement benefits are numerous when using manure.

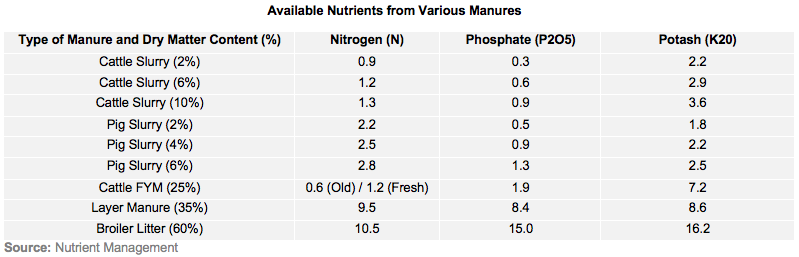

To work out how many nutrients will be provided by an application of manure spread, multiple the spreading rate (m3/ha or tonnes/ha) by the values in the table. For example, a 6% Dry Matter Cattle Slurry applied at 25m3/ha will provide a 30kg/ha of total available nitrogen (1.2 x 2.5).

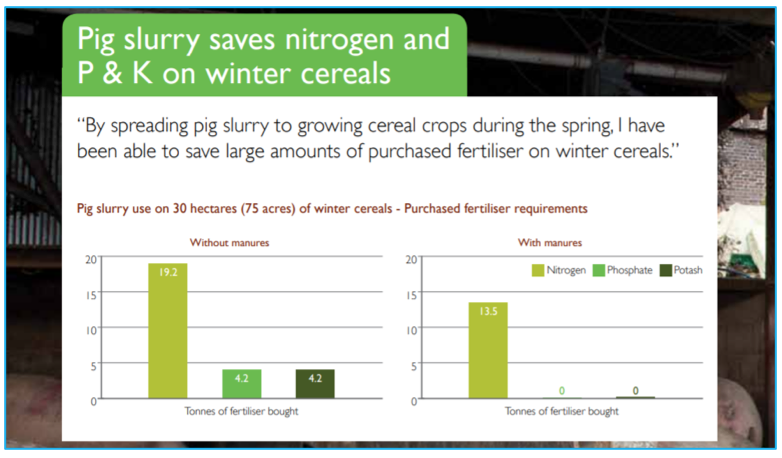

The same author demonstrates the benefits on an arable crop.

Manures can also provide additional sulphur (SO3) and Magnesium (MgO), as well as smaller amounts of trace elements. Where possible, you should carry out a soil test to ensure you’re matching the plants’ needs. Excessive nitrogen can cause crop lodging and a good rule of thumb is not to use more than 50 m3/ha of slurry, as this carries environmental risks from leaching and runoff as well.

Conclusion

Manure application is very consistent with SA and SIA principles as it uses waste products that are otherwise difficult to dispose

of. Its application can help increase yields or and reduce production costs. However, responsible use is needed.

Other Opinions You Might Be Interested In…

- Sustainable Agriculture: Arable Farming

- Sustainable Agriculture: Arable Nitrogen Use

- Sustainable Agriculture: Tackling Fertilizer Waste Head-On

- Sustainable Agriculture: Advanced Technology to Improve Yields