Insight Focus

- Surplus Thai ethanol is increasingly being used to make bioplastics.

- Bioplastics are often biodegradable.

- They also have a lower carbon footprint than conventional plastics.

Why Bioplastics?

Thailand has a surplus of ethanol.

The government has shifted away from ethanol and is instead supporting electric vehicle adoption, leaving the ethanol industry in a difficult position. Some producers are exploring whether they can convert this into bioplastics.

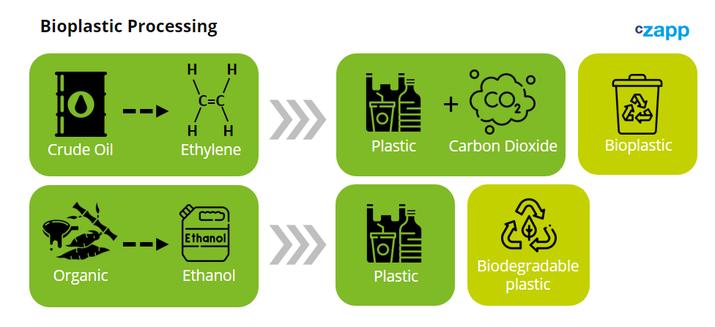

Bioplastics are made from renewable resources, not fossil fuels. They are frequently biodegradable under the right conditions. They also result in reduced carbon dioxide emissions than conventional plastics across their entire lifecycle.

For example, a lifecycle analysis of polylactic acid-based cups and lids has shown that their manufacture and transport consumes 30-50% less energy and emits 24-55% less greenhouse gas than conventional plastic.

Adoption is increasing; in Europe all plastic packaging on the market after 2030 will be generated from renewable raw materials and recycled via current recycling system.

Bioplastics also have a wide range of applications:

- Packaging: food and beverage, cosmetics, food wrap;

- Agriculture: soil cover, nursery bags;

- Electronics: Phone cases, speakers, keyboards;

- Pharmaceutical: Artificial skin;

- Synthetic fibres: diapers, coffee filters.

As a result of increasing plastic packaging demand and stricter environmental regulations that promote bioplastic use, we expect demand to keep growing in the future.

Thai Government Supports Bioplastic Growth

Thailand has the potential to become a bioplastics hub. It’s a major cane grower with excess ethanol availability for fermentation. Its strategic location in the centre of Southeast Asia means it can market its bioplastics across the region. China is already the world’s largest bioplastic consumer, alongside the USA and EU

Government policy is also supportive of the industry; it’s keen to reduce reliance on imported fossil fuels to boost energy security.

From January 2019 to December 2021, Thailand’s cabinet approved a green measure to promote bioplastic packaging by offering a tax deduction up to 125%.

Now the Royal Decree 749 is in place which contains measures to promote biodegradable plastic packaging.

The decree extends the additional 25% deduction for costs incurred by companies for certified biodegradable plastic products, which was introduced by Royal Decree No. 702 with effect from 1 January 2019 to 31 December 2021.

Under Royal Decree 749, the additional 25% deduction is extended until 31 December 2024. The tax policy is expected to motivate 10% of existing plastics companies to transition to bioplastic production.

The Board Of Investment of Thailand also provides tax and non-tax incentives for Bioplastic companies.

Some non-tax incentives include: permission to bring in expatriates, land ownership and no restriction on foreign currencies.

To increase ethanol use across various industries, including bioplastics, the government has also:

- Developed technical standards for ethanol production;

- Overseen ethanol procurement to address supply shortages;

- Facilitated skills development for farmers and ethanol producers;

- Amended state-level regulations to support ethanol use.

Thailand’s Industrial Development Strategy 4.0 (2017-2036) also emphasizes the sustainable and eco-friendly growth of the petrochemical and plastics industries.

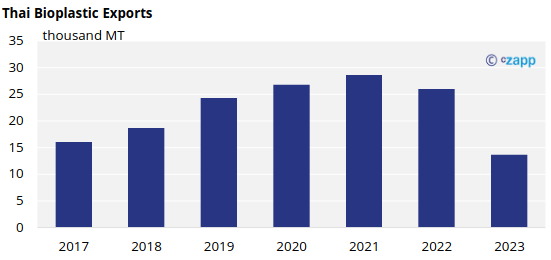

Export volumes are therefore increasing.