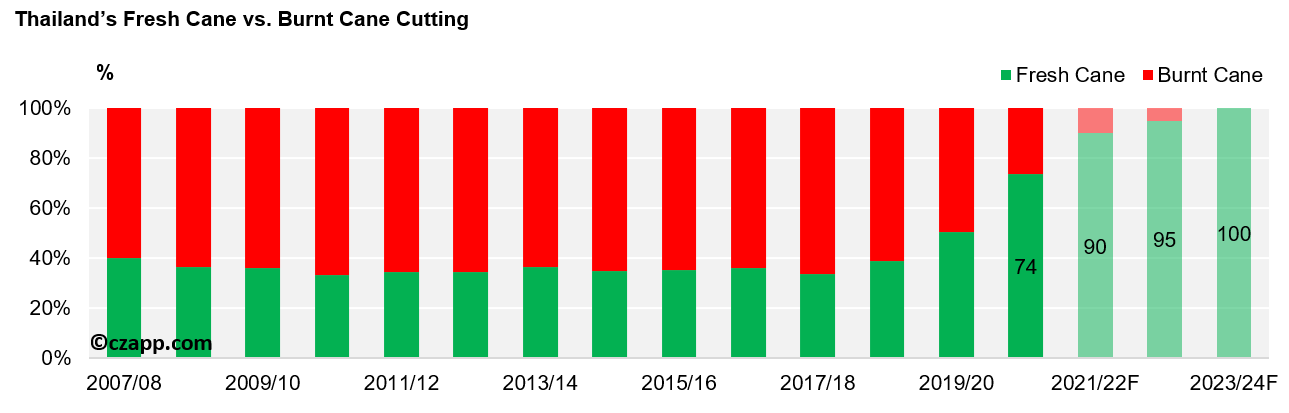

- Thailand has been reducing the amount of sugarcane it burns each year.

- This makes sugar production more environmentally friendly and sustainable.

- It also improves the raw sugar quality, making it cheaper to process.

Burnt Cane Issue

- In recent years, the Thai sugar industry has faced growing pressure from the Government and environmental groups to reduce sugarcane burning.

- The burning of sugarcane has often been linked to high levels of smog and pollution across Thailand.

- As a result, the sugar industry has drastically reduced the proportion of cane that is burnt, and has a target for no burning by the 2023/24 season.

- As an alternative to burning, many Thai mills have now invested in cane harvesters that cut the cane.

- This is known as fresh cane.

- The only other way to harvest fresh cane is by hand, which is very labour intensive and expensive; burning the cane is much faster and cheaper.

- As a further incentive, farmers now get paid more for cane that is not burnt.

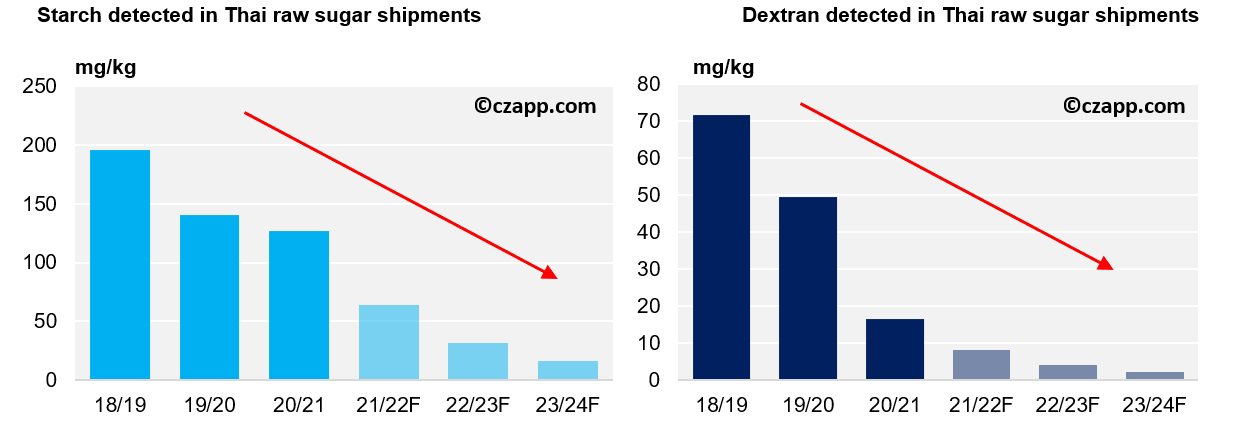

- When the cane isn’t burnt, the raw sugar extracted is of a much higher quality with fewer impurities.

- This leads to lower processing and refining costs.

- This is because cane burning leads to contamination with dirt and sand, which leaves more ‘unfilterables’ such as starch and dextran.

- Therefore, refiners need to consume more power (leading to higher costs) to remove the unfilterable content in the refining process.

- Many global refineries include penalty scales in their contracts to protect against the possibility of receiving sugar with a relatively high proportion of unfilterable material.

Factors That Cause Higher Levels of Starch and Dextran

- Cane burning.

- A longer time between the harvesting and the crushing time.

- The climate conditions and the exposure to the dirt and mud.

- Samples collected from many raw sugar shipments already show that levels of starch and dextran are falling.

- It is worth noting that some milling groups are already above 90% fresh cane and have even lower levels of unfilterables in their raw sugar.

- As Thailand works towards the target of zero burnt cane by the 2023/24, we expect starch and dextran levels to continue to improve.

Why is Starch and Dextran so Important to Quality?

- Starch and dextran cause a big headache when it comes to the refining process.

- In the refining process, the two most important factors are the polarization and the crystal size distribution of the raw sugar.

- The presence of dextran significantly affects both the polarization and the crystal size.

- Unfilterable material gives a lower rate of filtration and reduces the rate of heat transfer (more heat energy needed).

- It also lowers the rate of crystallization and increases the pan boiling time and centrifugal power consumption.

Other Opinions You Might Be Interested In…

Explainers You Might Be Interested In…