Insight Focus

The October East Coast strike highlighted the efficiency challenges of US ports. Automation is seen as a potential solution but remains contentious due to concerns over job security. A balanced approach is needed to modernise ports while addressing worker concerns.

Recent Strikes Expose Vulnerabilities

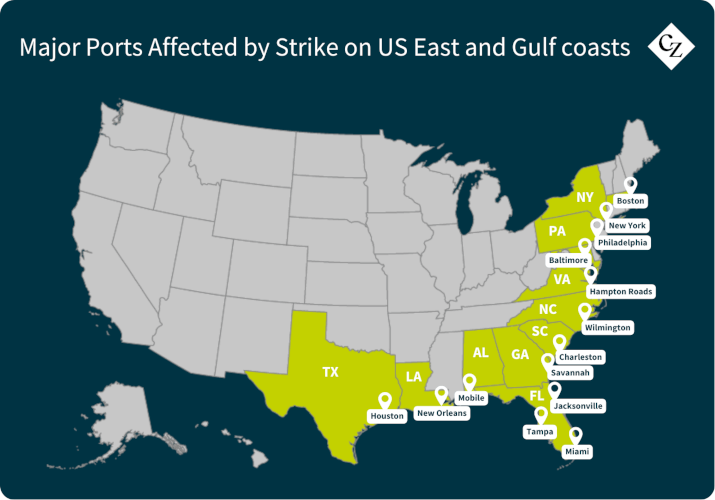

The recent three-day strike on the US East Coast in early October exposed some vulnerabilities in US port operations, raising critical questions about their preparedness and ability to improve efficiency.

Despite advance notice from port workers about their intention to proceed with a strike action, port authorities and operators failed to develop an effective mitigation strategy. Although the strike lasted only three days, its impact was substantial, underscoring the fragility of US supply chains.

Key consequences included emergency surcharges by ocean carriers, a backlog of over 40 ships carrying billions of dollars in cargo waiting to offload, and significant delays in transit times. The chaos created in just 72 hours required weeks for the supply chain to recover fully. The industry shudders at the potential cost and disruption a longer strike could bring to the US and the global shipping sector.

US Ports Struggle with Efficiency

Efficiency remains a significant challenge for US ports, which lag behind their global counterparts. According to the World Bank’s Container Port Performance Index 2023, the highest-ranking US port, Philadelphia, only placed 50th worldwide. Other US ports included in the global top 100 were Charleston, Port Everglades, Wilmington, Boston, Miami, Jacksonville, Halifax, and New York & New Jersey.

In stark contrast, the top-ranked ports globally included Yangshan in China, Salalah in Oman, Cartagena in Colombia, Tanger Med in Morocco and Tanjung Pelepas in Malaysia.

This performance gap poses challenges as global competition intensifies. With geopolitical conflicts disrupting shipping in regions such as the Red Sea and Ukraine, and potential trade pressures—such as the recent announcement of new tariffs on US imports—US ports must enhance their efficiency to handle crises effectively.

The Potential of Automation

One of the best ways to make strides in efficiency is by incorporating port automation, a potential game-changer for ports. Advanced technologies and machinery can expedite daily tasks, increase accuracy and streamline operations. However, in the US in particular, this remains a contentious issue between worker unions and port operators, often leading to disruptions.

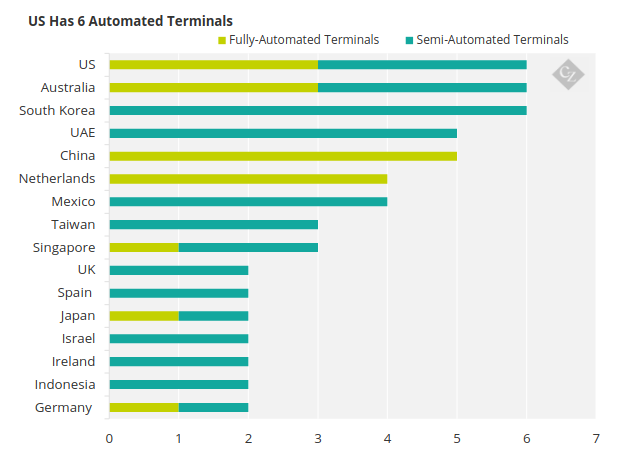

Although the US seems to be a leader in port automation with six automated or partially automated terminals, it is worth noting that the US has over 300 ports – many of which have multiple terminals.

Source: Port Economics

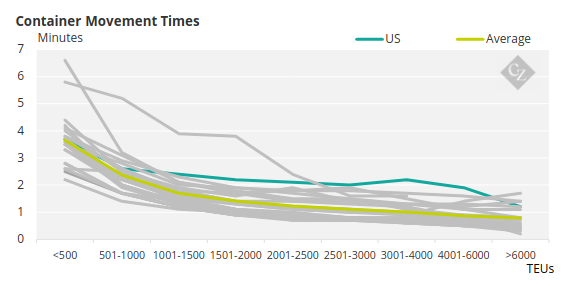

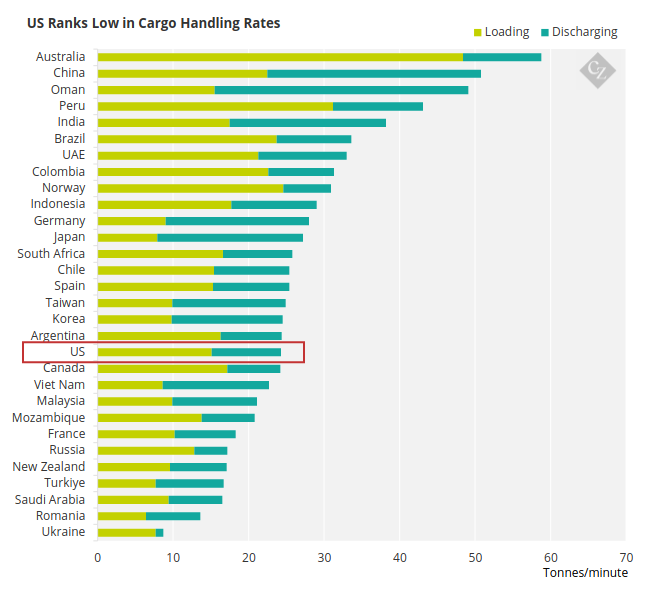

Port workers fear that widespread automation could jeopardize job security and make their roles redundant. This resistance has led to strikes and protests, as unions on both West and East coasts of the US leverage their considerable influence to limit automation. US ports remain some of the least efficient globally in terms of container handling.

Source: UNCTAD

Worker concerns could be partially valid: automation could replace certain manual tasks currently handled by dockworkers. However, automation doesn’t necessarily equate to fewer jobs.

Instead, it may shift the nature of the work, creating roles in machine operation, control room management and maintenance, while elevating the skill requirements and professional profile of many existing port positions. For some workers, however, particularly older employees, this transformation might seem daunting, leading to resistance.

Finding Common Ground

A collaborative approach could help ease the transition to automation while addressing union concerns. This includes continuous education, comprehensive training programs for new systems, and clear communication about the evolving nature of port work.

By embracing these changes, workers could secure positions in the modernised workforce, while ports could achieve the efficiency needed to stay competitive globally.

Source: UNCTAD

Ultimately, balancing innovation with job security will be critical for the future of US ports. Modernising operations without sidelining the workforce will require dialogue, adaptation and investment—but it remains the key to overcoming current vulnerabilities and achieving long-term efficiency.