- We know that farmers produce wheat, and to really understand how the wheat market works, we must look at the before and after.

- Cleaning, drying, and storing wheat correctly are of paramount importance.

- Planning and marketing for the onward chain are crucial to profitability.

What ‘Farmer’ Means to Most

When people think of a wheat farmer, they have the idea that they are a grower of our food. They also assume the following:

- They drive tractors pulling cultivators and drills to sow a good crop.

- They nurture the wheat through its growth stages, applying the necessary fertilisers and sprays.

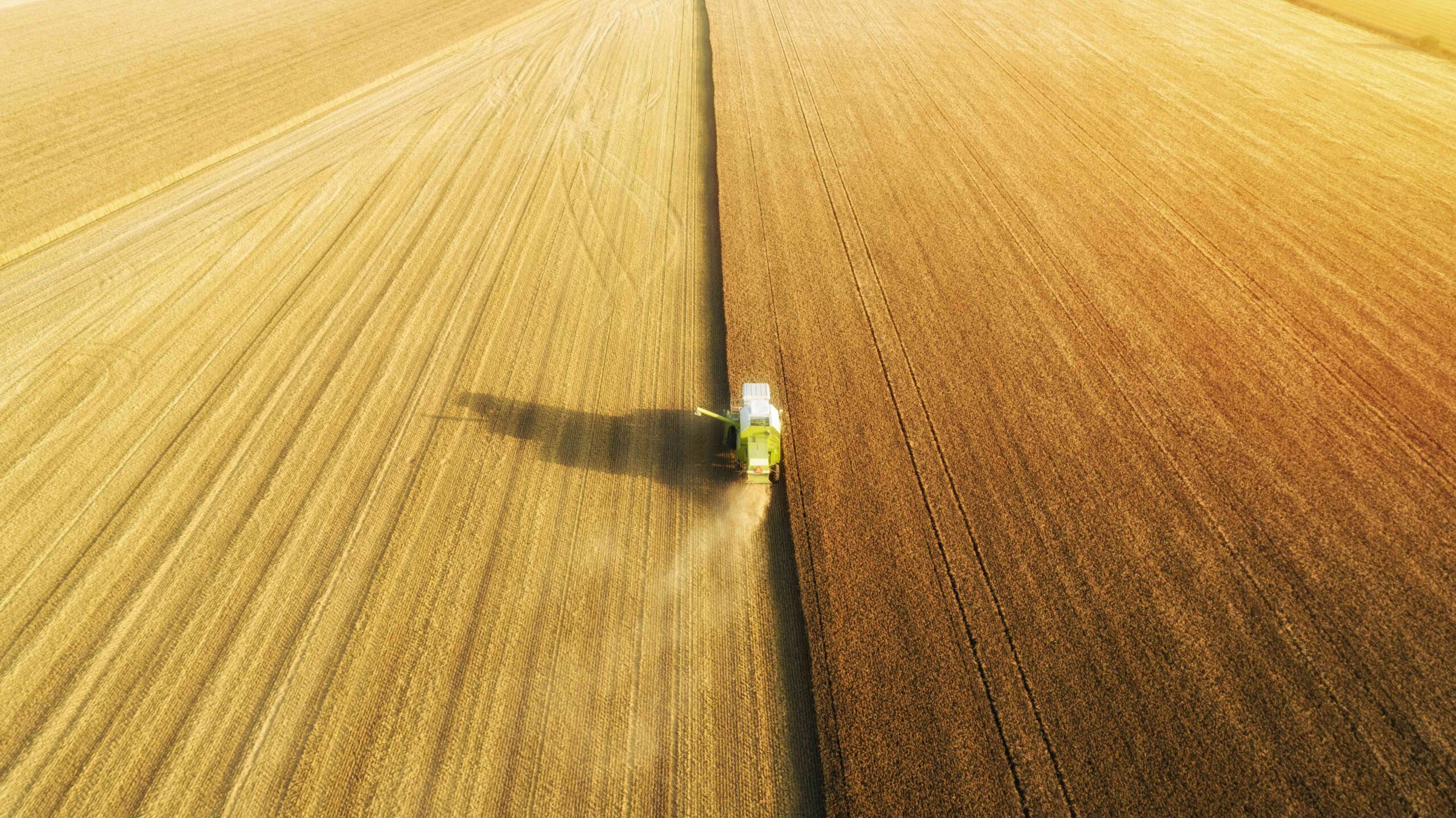

- They harvest the wheat on a sunny day bringing the annual farming cycle to a close.

These stages of the wheat grains’ journey come as no surprise. The phases that come before and after are less well understood.

Planning, quality assessment, storage, marketing, pricing and onward logistics add a number of complications to the subsequent progress and profitability of the wheat’s journey.

Planning

Even before the first seed is planted, planning for the wheat to leave the farm in 12-24 months has begun in earnest.

Farmers do not generally grow wheat after wheat. Different crops are rotated, which maintains condition and structure of the soil. This will influence what wheat is sown.

Soil type will be relevant when deciding on Winter or Spring, Hard or Soft, milling or feed quality ambitions. A suitable variety can then be chosen.

In all of these decisions, a marketing strategy and the final destination must never be forgotten. There is little gain in producing a crop without a sensible, and hopefully profitable, destination in mind.

Post-Harvest Quality

As we have discussed in previous articles, quality will likely depend upon the type of wheat (winter or spring; hard or soft).

Agronomic inputs in the form of sprays and fertiliser will also have a fundamental bearing on quality, not forgetting the ever-important weather throughout growth and harvest.

Drying and storage of the wheat are critical to maintaining the quality and end use of the grain. A lower specification wheat will be easier to dry and store, preserving the minimal quality needed. In comparison, the careful conditioning of the best quality milling wheat is essential in conserving the high requirements of the flour miller.

In addition, cleaning, by passing grains over sieves or even high-tech gravity tables and/or colour sorters, will help reduce the admixture and potentially the final price obtained.

Storage

Long-term storage over many months requires the wheat to be dried, most commonly to below 15% moisture and maintained in good condition.

Once dried and in the store or silo, temperature is a major factor in preserving the general condition of the wheat and preventing bug infestations.

Cooling grains to low temperatures, perhaps as low as 5°C, will render the environment too cold for grain mites and weevils to survive and be active. Nonetheless, these store pests have an uncanny ability to appear in abundance at any point that temperature and/or moisture is allowed to rise.

Ensuring cool temperatures is not so easy once winter has passed, when warmer spring and early summer ambient conditions become the everyday norm.

Bug infestations will almost inevitably ruin the quality for the best milling wheats and confine them to basic feed wheat after the expense of debugging.

Planning Ahead and Marketing

It is all very well being the best grower in town and storing wheat in good condition, but moving wheat on is where the farmer gets the value for their crop.

In our next edition, we’ll look at the marketing, pricing and selling of wheat beyond the farm gate.

Other Opinions You May Be Interested In…