Insight Focus

Bottled water demand is rising, pushing innovation in sustainable packaging. Companies are responding with eco-friendly solutions like rPET to reduce plastic waste. Brands must now balance sustainability with product quality and accessibility.

Sustainable Plastic in Demand

The demand for bottled water has steadily increased, driven by convenience, health concerns, and, in some areas, limited access to clean tap water. While consumers are more conscious of the environmental impact of plastic packaging, plastic bottles remain the most common—and most practical—choice for water packaging.

However, with 52% of consumers indicating that reducing single-use plastic is a priority, companies are innovating to meet both the demand for bottled water and the growing desire for sustainability.

Plastic packaging producers, like Cyprus-based multinational manufacturer RETAL, are responding to these pressures by offering sustainable alternatives, such as recycled PET (rPET) preforms and bottles for the beverage industry.

RETAL uses rPET and NEOPET Cycle from sister company NEOGroup, which is a virgin PET with rPET flakes already integrated. This not only contributes to a circular economy but also helps lower the carbon footprint of final packaging without compromising on quality.

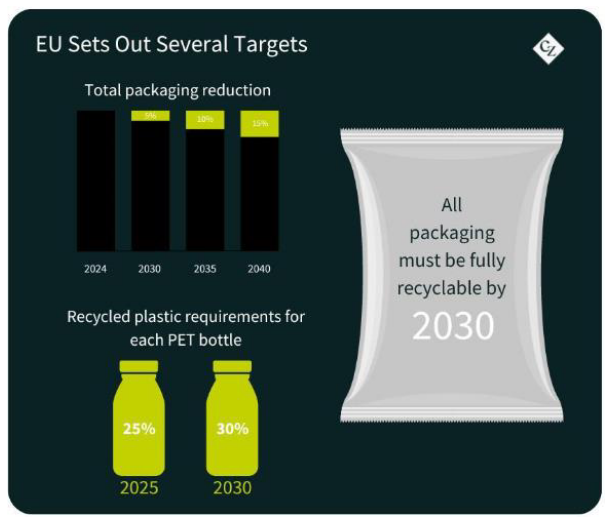

The use of rPET is increasingly favoured by mineral water and beverage brands looking to increase the sustainability performance of their packaging and comply with coming EU regulations (SUPD and PPWR).

Alternative Packaging Problems

Other packaging materials, like aluminium or multilayer Tetra Pak cartons, have been proposed as alternatives, but their sustainability credentials are less easy to explain. For instance, while aluminium cans have seen a rise in sales—tripling since 2019—their production is energy-intensive. Tetra Pak recycling is also not a closed-loop system, often leading to downcycling rather than reuse.

Understandably, consumers find it difficult to know how—or even if—these cartons can be recycled. These factors make rPET a more viable option for companies that prioritise environmental impact without sacrificing product accessibility, particularly as this is the most easily recycled material in standard packaging collections.

The Future of Sustainable Bottled Water

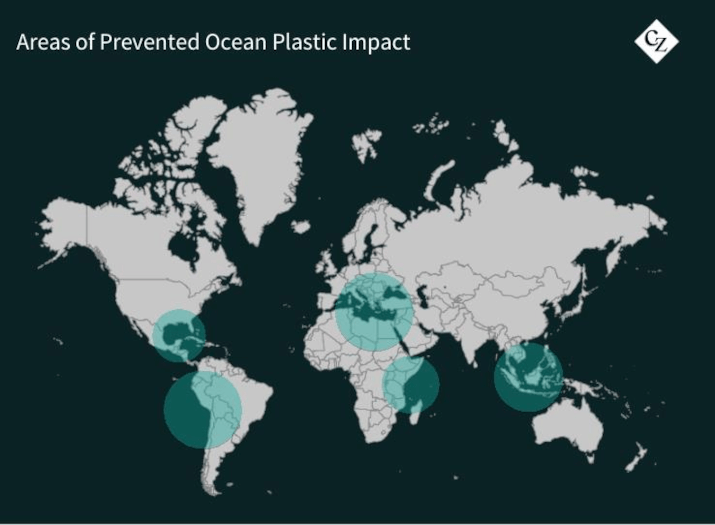

NEO WTR became Europe’s first beverage brand to use 100% certified Prevented Ocean Plastic bottles, made from recycled materials collected from coastlines at risk of ocean plastic pollution. This initiative not only supports sustainable packaging but also provides social benefits, offering local collectors in countries like Indonesia a consistent income while preventing plastic from entering the ocean.

Nigel McNally, MD of Brookfield Drinks, which includes NEO WTR in its portfolio, explains, “Innovation in plastic technology is crucial, and we must continue to look deeper and make real progress to support the circular economy.”

He added that NEO WTR works with a partner that provides full end-to-end traceability of the entire collection and recycling process for Prevented Ocean Plastic, from origin beaches to the final production-ready material, whilst also guaranteeing social equity by ensuring bottle collection provides a reliable income option for its collectors.

The waste plastic is collected by local people, who are paid either in money or coupons that can be exchanged for commodities. The plastic waste is then sent to a production plant where the raw material used to create NEO WTR bottles is produced. The process is highly transparent, with a fully documented chain of custody from collection to delivery, and is independently audited by third parties. It is even possible to determine exactly which beach the plastic was collected from.

The rise in demand for bottled water shows no signs of slowing, and it is up to manufacturers and brands to offer sustainable, affordable plastic bottle options that meet consumer needs while addressing environmental concerns. Through innovations like rPET and programs such as Prevented Ocean Plastic, the industry is beginning to tackle the issue of plastic waste head-on.