- The fashion industry is looking to increase its use of recycled plastic content in clothing.

- With packaging and textiles utilising the same plastic bottle pool, is there enough to go round?

- New technologies are emerging for textile-to-textile recycling, but greater investment is needed.

The RPET Supply Crunch

Despite a steep premium over virgin plastics, packaging manufacturers are still clamouring to get their hands on RPET to meet ambitious sustainability goals. However, the packaging industry isn’t the only one gobbling up RPET supply.

In the last decade, the fashion industry has started to incorporate recycled plastics into clothing in a bid to up its sustainability game and move away from virgin plastics. Everyone from H&M to Nike to Louis Vuitton is including a recycled plastic component in their collections.

But there’s a problem. Demand for recycled materials from the fashion industry is eating into the RPET bottle market and exacerbating limited supply.

Green Garments

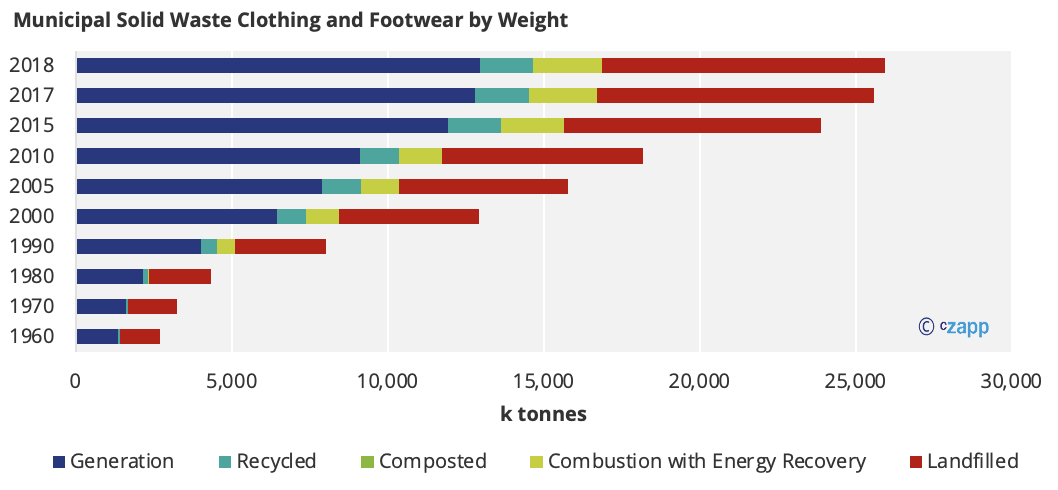

The fashion industry, however, has a whole other pool of plastic it can source from – used textiles – and it’s a big pool. 69% of the almost 13m tonnes of clothing and footwear produced each year is sent to landfill.

Textile recycling is also costly and there are few technologies that have been developed to address the issue. But now, more and more developments are being made that may allow the fashion industry to close the loop on plastics.

Closed-Loop Textiles

According to the European Environment Agency, textiles are the third-largest contributor to plastic waste generation globally given that recycling of synthetic fibres does not take place at scale.

As the fashion industry comes under further pressure to improve its sustainability credentials, new initiatives and technologies are emerging to support greater circularity.

Ambercycle is a technology that approaches textile recycling in a sustainable way. The group takes post-consumer textiles and reduces them to yarn form that can be reused in future garments.

The yarn created – trademarked Cycora – is a purified polyester, meaning materials are blended. The yarn can essentially be broken down and reused infinitely.

The Lycra Company has also recently developed a process that can convert textile scraps from garment manufacturers into new fibres. The Coolmax and Thermolite EcoMade fibres have similar properties to virgin polyester and are available in the form of staples or filaments. Having previously made the Coolmax and Thermolite EcoMade fibres from RPET bottles, this move to textile scraps is an example of a company examining its production chain to find greater circularity within textiles.

Engineering New Materials

In a similar vein, a growing amount of research is focused on improving material properties to eliminate the need for blends.

Poly-blend fabrics were developed as a way to combine properties of different materials. In a polycotton shirt, for instance, the durability from the polyester is complemented by the breathability of cotton, creating a long-lasting, comfortable product.

Research is now uncovering new uses for existing materials in textiles. Earlier in the year, researchers from the Massachusetts Institute of Technology discovered that polyethylene is a promising polymer for textiles as it provides lightweight cooling properties.

The group engineered single-material PE high-performance fabrics that can be fully recycled in an automated process. The 100% PE garments provide ideal properties for clothing without the need to blend, therefore making recycling much easier and cheaper.

Investments

According to Kate Daly, Managing Director at Closed Loop Partners, plastics in end-of-life textiles are viable feedstocks for a range of advanced recycling technologies. The problem is that the technologies are only just beginning to emerge, and significant investment is required to advance these complex manufacturing techniques.

Progress is being made, though. On the 2nd November, Northern Europe’s largest recycling centre for discarded textiles officially opened its doors in Paimio, Finland. The plant should process 12 million kg of textiles each year, reusing it as quality raw materials.

BlockTexx, an Australian start-up, also received a $5.5 million investment to build a commercial-scale textile recycling plant in Queensland this year. BlockTexx uses technology developed in partnership with researchers from Queensland’s University of Technology to specifically separate hybrid fibres with the ability to turn cotton into cellulose and polyester into flake. It can therefore produce a product that’s comparable to the virgin material.

Swedish company, Renewcell, uses a slightly different technology to recycle clothes and turn them into new garments. The eco-friendly chemical recycling process reduces materials to a pulp, which is processed into a fibre and turned into a thread. The plant secured a €30 million loan with the European Investment Bank this year.

Concluding Thoughts

- Increased demand for recycled content from the food and beverage sector, coupled with its willingness to pay steep premiums over virgin, will ultimately constrain RPET supply for textiles.

- Moving towards a closed-loop textile-to-textile approach would improve supply and benefit multiple industry sectors.

- Unlike many other plastics, though, infrastructure for the collection of clothing is widespread.

- The bottleneck that the fashion industry faces is therefore investment in the large-scale recycling of end-of-use clothing.

- However, sustainable, recycled content will come at a premium – something the beverage sector and consumers have been willing to pay up to now.

- Will fast fashion customers be willing to stomach the additional cost in the same manner?