Insight Focus

Growing malting barley requires careful planning and expertise. Key factors include soil type, seedbed preparation and fertiliser management. Proper harvesting, drying and storage ensure high-quality samples meet market specifications.

The challenges of growing malting barley are not for the faint-hearted or inexperienced arable farmer. Beginning with meticulous planning, all the way to the grain harvested in the summer months, constant attention to detail is vital to achieve success and profit.

The Planning

Malting barley can be grown either as a winter or a spring crop. However, the vast majority are spring varieties, and thus these are our focus.

Spring barley fits extremely well into crop rotations with wheat and other break crops, such as pulses and oilseeds. There are several advantages to growing spring barley in a rotation, although if it is intended for malting, a number of factors must be established well in advance of spring planting.

Expertise

Spring malting barley is not straightforward for the arable farmer to grow. It is difficult to produce a top-quality, high-profit-margin sample. Therefore, it is best grown by those with experience and a deep understanding of their soil types.

Soil type

Lighter soils, such as chalky soils, generally produce a more easily managed crop with a better-quality sample than heavy clay and cloddy soils.

Market

Due to the premiums afforded to the best malting barley samples, it is important to identify and grow a crop with a specific market in mind. This could be a local maltings or, indeed, the wider export trade. Either option, or both, will depend on the geographical location of the farm.

Long-distance transport to the destination can lead to very painful costs if lorries are ultimately rejected on quality grounds by their desired maltings or export facility upon arrival, which will be months after the original decision-making. The market will have a significant influence on the variety of barley subsequently planted, as well as how it is grown to meet this demand, particularly in terms of nitrogen specification.

Drying and storage

It is imperative that any grower of quality malting barley has access to good drying and the necessary, potentially long-term, storage facilities to maintain optimum sample quality post-harvest.

Decision making

Having assessed the farming rotation, soil type of relevant fields, market and drying and storage facilities, only then can the most appropriate variety be selected with quality parameters in mind to aid in growing and agronomic input.

The Growing

Attention to detail from start to finish is crucial to obtaining a useable sample for your maltster buyer.

The Seedbed

Historically, fields would have been ploughed to bury previous crop residues and leave the soil to weather through the cold winter months. This would ideally be followed by a single cultivation pass in the spring to create a fine and even seedbed.

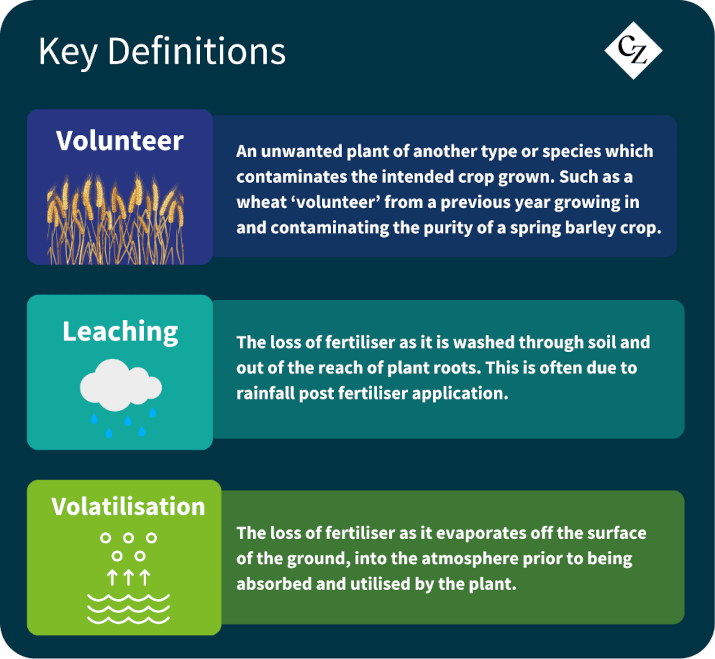

Today, ploughing is used much less extensively as techniques have evolved. Nonetheless, it is imperative that the seedbed is well-prepared, with residues from any previous crop kept to a minimum to avoid any ‘volunteer’ cross-contamination.

Drilling

Planting can begin early, but the usual period in the UK is from February to April. It is imperative that the soil is warm and moist enough, along with a well-prepared seedbed. This will ensure optimum seed-to-soil contact, enabling swift germination and plant emergence.

A pre-seeding herbicide, such as glyphosate, will help prevent unwanted competition for the young plants.

Due to the need for an uncontaminated post-harvest sample, it is critical that the seed is well-sourced and known to have good varietal purity.

The ideal seed rate will depend on timing and seedbed quality. The most cost-effective approach is to aim for an optimal date, seedbed, moisture and warmth, allowing the seeds and young plants the best opportunities to grow and emerge. This will allow for a lower seed rate than an early or late drilled crop, into less-than-ideal conditions.

Sprays and fertilisers

Spring barley does not tolerate high levels of pre-emergence herbicides. Therefore, these need to be carefully calculated and balanced by the fact that it is a competitive crop that, with rapid growth, should achieve good, consistent field cover.

Fertiliser is absolutely critical. Previous crop history, manure applications and general soil health must be considered in relation to application rates, especially nitrogen. Too little nitrogen, and yields will suffer. Too much nitrogen, and the final sample specification may have too high a nitrogen content for the buyer, with significant financial implications.

Additionally, fertiliser timing is essential to optimise uptake for the growing plants while minimising residue nitrogen levels in the final grain sample, which could render it unfit for malting. Avoiding leaching or volatilisation, which deprives the crop of much-needed nutrients, is of equal importance.

Harvesting

When harvesting malting barley in the summer months, most commonly in August in the UK, the need for a dry and clean sample is paramount. It should be harvested as a priority over other grains and oilseeds, where there is less price sensitivity to quality.

As discussed in our previous article, contract specifications for the onward buyer must always be at the forefront of a farmer’s mind when making decisions.

Challenges

Any farmer wishing to grow malting barley has a plethora of planning considerations:

- Soil type

- Market and variety

- Seed bed, rates, and timing

- Spraying and the critical role of fertiliser

- Harvesting and obtaining the optimal sample

Once the above is achieved, drying, conditioning, sampling, testing, storing and delivery of the final grain are the next hurdles to overcome.

A farmer growing consistently good malting barley can achieve success and satisfaction that many can only aspire to. It can be the most frustrating and yet the most rewarding crop on the farm!