Raw sugar is the form sugar takes after the first processing stage of cane or beet sugar. However, it is not fit for human consumption in this form, and instead requires further refining to become food grade. After this process, it has become white sugar – a food-grade product that requires more careful handling. In this guide, we explain the key differences between raw and white sugar.

Pure sugar is 100% sucrose. Pure sucrose is a white crystalline solid.

Outside of a lab, pure sucrose rarely exists. Sugar almost always contains impurities which usually result from its extraction from sugar cane and sugar beet.

To extract sugar, cane is crushed or beets are sliced. The sucrose within them is then extracted by dissolving in water and this liquor is then crystallised. But impurities from the cane/beet plants and the process are still present.

Raw sugar is only made from cane crushing at a sugar mill. It contains a high level of impurities and so is usually brown in colour. It can also have a slightly bitter flavour. Raw sugar is not fit for human consumption and needs further processing at a refinery. This means that raw sugar can be transported like any other bulk commodity: loose in a truck, in a rail car and loaded directly into a ship’s hold.

In contrast white sugar can be made from cane crushing at a sugar mill, from beet slicing at a sugar factory or from processing raw sugar at a refinery. White sugar has fewer impurities and so is usually white or off-white. It is fit for human consumption and so is a food product, not an industrial product. This means it must be handled according to strict hygiene protocols. For example, most white sugar is transported in double-lined polypropylene bags or food-grade tanker.

There are two main ways to assess the purity of sugar: polarisation (“pol”) and ICUMSA.

Polarisation

Polarisation is a measure of the amount of impurities in a sugar sample. Pure sucrose has a pol of 100 degrees. The lower the pol, the more impure the sample. High-quality refined sugar generally has a pol exceeding 99.7 degrees. Lower-quality white sugars typically achieve 99.5 degrees. High-quality raw sugar typically reaches 99.3 degrees. Poor quality raw sugar can fall below 96 degrees on occasion.

Different sugar producers make different grades of raw sugar. Here’s a table of common qualities.

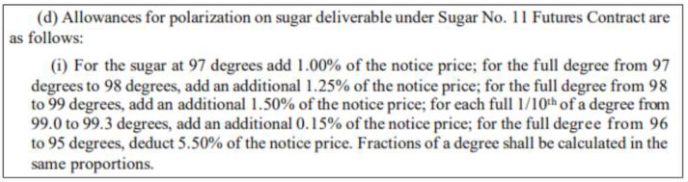

The No.11 raw sugar futures benchmark assumes 96pol raws, which is towards the low end of the quality spectrum. This means a sample of theoretical “No.11 raws” would contain less sucrose and more impurities than many grades of raw sugar produced commercially today, and so would be less valuable for any purchaser. For this reason, a pol premium is paid for raw sugars which exceed the 96pol benchmark.

Source: ICE FUTURES U.S., INC.

ICUMSA

ICUMSA is a measure of the sugar’s colour. The lower the number the less colour it has and so the whiter it appears. High-quality refined sugar is 50 ICUMSA or lower. The No.5 refined sugar futures benchmark is for 50 ICUMSA white sugar; sugar with a higher ICUMSA cannot be delivered against this futures contract. Lower-quality white sugars typically range between 50-150 ICUMSA. Raw sugars’ ICUMSA can range from the low hundreds to the low thousands.

Most food and beverage companies have strict ICUMSA limits for the sugar they use to avoid compromising the quality of their products.

Brown Sugar

Food-grade brown sugar is not the same as raw sugar. Raw sugar is an industrial product which needs further processing to be suitable for human consumption. Brown sugar is suitable for human consumption. The brown colour comes from impurities which have been deliberately left in the sugar. These also change the taste and moisture levels of the sugar. The colour can be made either by not processing the sugar as far as refined sugar is, or by taking refined sugar and adding molasses back into the sample.