Introduction

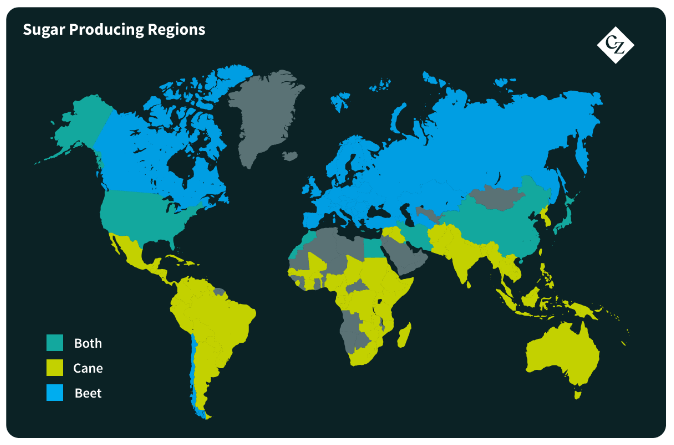

Sugar comes from two crops: sugar cane (which accounts for 80% of total sugar production) and sugar beet (which accounts for the remaining 20%). Both crops produce sucrose and there is is no chemical difference between the end product, although beets only make high quality white sugar whereas cane can make a range of sugars from low-grade raws all the way to high quality whites. Cane and beet are grown in different climates across the globe.

Sugar Beet Production

Source: Shutterstock

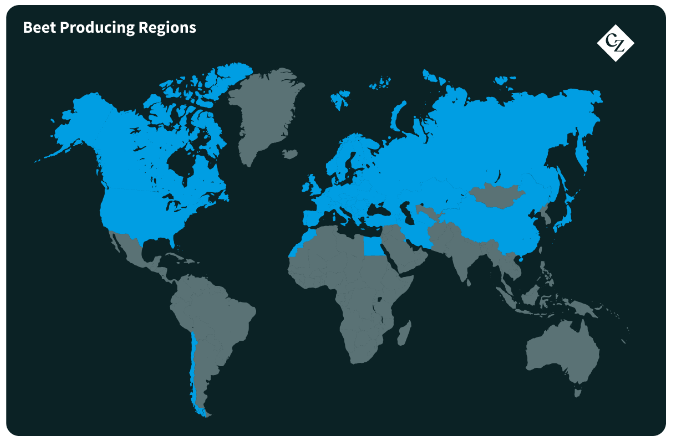

Sugar beet is a pale brown root crop that thrives in temperate regions. Currently, Russia and Europe are the largest beet-producing regions in the world. Sugar beet is a popular among farmers because it is a good rotation crop. This helps to maintain soil quality and prevent pests/diseases.

Sugar beet is a biennial crop. The first year is when the taproot is established and sucrose concentration occurs. In the second year the beet flowers and produces seeds. Therefore, it must be harvested before year two when the energy from the sucrose is expended.

Sugar beet grows substantially during the first year. Seed germination occurs one to two weeks after planting if conditions are good. To protect the beet during its development process, especially before the leaves are fully formed, farmers need to control weed growth in the field.

Sugar beet has a relatively long growing period, normally from 140 up to 200 days, and sugar is formed in the root. It is a relatively difficult crop to grow. It’s susceptible to numerous diseases and pests, including Beet yellow virus, Aphids, Beet Cyst Nematodes, Beet Leafhoppers, Beet Webworms, Blister Beetles, Cutworms, European Corn Borers, Flea Beetles, Leafminers, Rove Beetles, Seed Corn Maggots, Spider Mites and Vegetable Maggots.

It is also not frost-tolerant. If the frost arrives once beet seeds have germinated, it’s possible the seedling dies and the area needs to be resown. Once the roots have grown, if the soil freezes before harvest the cell walls in the root can rupture, leading to loss of beet structure, making it harder to process and the sucrose in the beet also degrades. Therefore, the length of the growing campaign depends on when spring and winter arrive geographically. For example; Russia has shorter beet seasons than southern Europe.

During its growing season, beet requires decent rainfall and sunshine. Too little soil moisture means the root becomes spindly – long and thin as it burrows deeper looking for moisture. Too little sunshine and the leaves won’t photosynthesise enough sucrose. The soil must also be loamy enough that roots can penetrate without obstruction, but also hold enough nutrients and moisture for the root.

Once fully mature, beet has a sugar content of approximately 13 to 18 percent, depending on the region. The average yield of sugar beet crops worldwide was 58.2 tonnes per hectare. However, its sucrose content varies in line with the length of the growing season, as well as other agronomic factors.

Sugar Beet is harvested during Autumn and Winter. Roots are extracted from the soil using a beet harvester and a rotor beater cuts off or ‘tops’ the head of the beet, which are then left in the field.

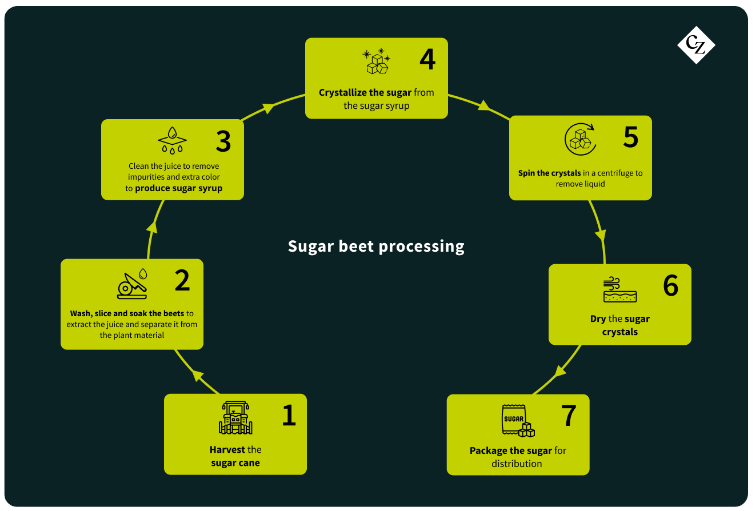

Once the beet is harvested, it is taken to a processing plant, or beet factory. Upon arrival at the processing plant, the beet is tested for quality and sucrose content. It is then placed on conveyer belts that transport the beet to a revolving drum showered with water, where rocks and gravel are separated and sink. The stones are then sold to landscapers or road builders as a by-product. The beets are then washed in a beet washer which cleans all the excess soil, while a magnet removes the metal fragments. The clean beets roll down towards the slicers, where they are sliced into ‘cossettes’ that look like small French fries. This opens the beet up, increasing the surface area and allowing the sugar to be more easily extracted.

The beet strips go into a large hot water tank where they are soaked to begin to break their cell membranes, allowing the sucrose to be extracted by osmosis. This occurs because the cossettes of beet have a higher sucrose content than the water surrounding them, making the sucrose diffuse into the water. At this stage, a brown sugary pulp is formed, entering a diffusion chamber that extracts as much sugar as possible from the cossettes by running them up against the flow of water. Then, the sugary liquid (raw juice) is ready for purification. The non-sugary pulp is pressed to remove any excess juice. It is then dried to form pellets which are sold as animal feed – a further by-product of the process.

The sugar syrup, or ‘raw juice’ is moved on to the purification process, where impurities are removed by adding milk of lime and carbon dioxide. During this process (carbonation) the CO2 and milk of lime combine to produce calcium carbonate, collecting the non-sugars. This precipitates out, clearing most of the impurities as it leaves the sugar juice. Some processors also add de-colouring ionic exchangers to decolourise the liquid.

Then, the residual juice is put through another filtration process using a frame or plate press. Pressure enables the sugar juice to be squeezed out, resulting in thin juice and solid waste. The waste, which is called lime solids and holds all the impurities, is then spread onto the farmland, enabling a further sustainable by-product: fertilizer.

The resulting ‘thin juice’, although much purer than the raw juice, has a relatively low sugar content. To increase the content, the thin juice is boiled to increase the sugar solids’ content from 16% to 65%. The syrup then goes through a 6-step evaporation process where the water boils off, leaving a thicker liquid.

The remaining ‘thick juice’ then goes through the crystallisation process. The water used in the process up until this point is then kept for further heating and use on-site, reducing waste and increasing energy efficiency.

The thick juice then goes through a four stage crystallisation process, the first of which passes it through a centrifuge (pressurised vacuum system) at a low temperature, where seed crystals are added, allowing sugar crystals begin to form and grow. The crystal sugar, now with a fudge consistency, is put in centrifuges to separate the mixture into liquids and crystals three times. The by-product that remains after the maximum amount of sugar crystals have been extracted is called beet molasses, and is used to manufacture animal feed or distilled into alcohol.

The sugar crystals are then dried with hot air and gathered, packaged, and distributed to consumers. And there we have it! The journey of sugar beet from seed to sugar.

Sugarcane Production

Source: Shutterstock

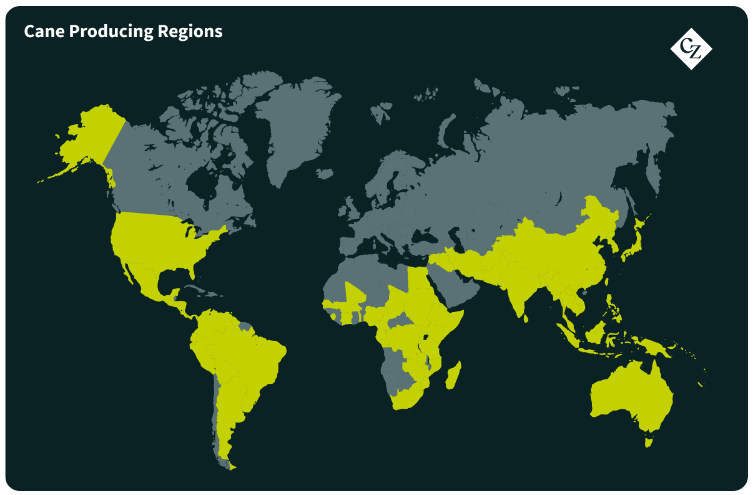

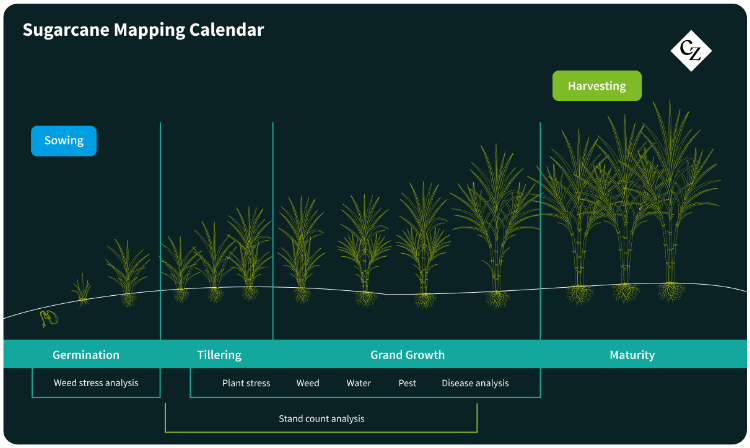

Sugar cane is grown in sub-tropical and tropical areas of the world. Brazil, India, Thailand, China and Australia are the leading global producers of sugar cane. Cane is a long-cycle crop. It takes 12-18 months from planting to yield its first harvest. Thereafter, the plant can be repeatedly harvested once per year, though sucrose content declines with each successive harvest.

Cane can be grown from seeds, but the most common method is to take sections of existing cane stalks and plant them directly in the ground. New cane shoots then form from the original cane plant.

Source: Shutterstock

The major factor determining cane growth is sufficient rainfall: up to 600mm of annual moisture is required. It is not frost tolerant.

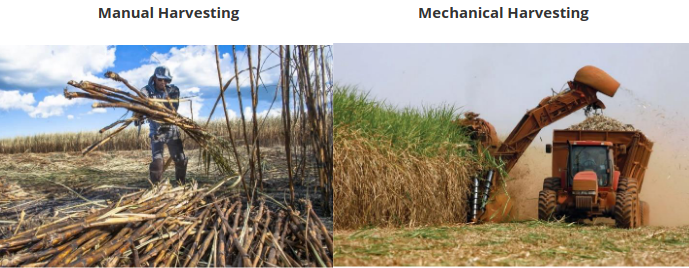

Sucrose forms in the cane stalk itself. The crop can be harvested manually or mechanically. If the cane is harvested manually the cane fields are often burned first to clear pest from the fields and cane leaves from the plants. Burning is not required for mechanized harvesting; the machine removes cane leaves. Once the cane is harvested it needs to be taken rapidly to the mill as it loses sucrose content rapidly.

Once sugar cane is harvested, it is transported to the mill. At the mill cane is processed into raw sugar. The cane is crushed into fragments which are then washed with hot water to extract sucrose. This liquid is then evaporated and crystallised.

During the production of sugar mills also produce molasses. Molasses is primarily used for the sweetening and flavouring food products, home baking, brewing ale, distilling rum, animal feed, flavouring tobacco products and as a defining component of commercial brown sugar.

When raw sugar has been produced from the sugar cane, it is often further processed into white sugar. Some mills have the capacity to produce whites; those that don’t sell their sugar to refineries. To produce refined sugar, raw sugar has to go through a purification process.

Many mills also generate the electricity using the cane fibre that is left after the cane is crushed. This means that sugar mills are self-sufficient in energy and can export power to the grid.

Sugarcane Ethanol Production

The sucrose in sugar cane can also be used to produce ethanol. This is most frequently done in Centre-South Brazil and India. Sucrose is extracted from sugar cane at mills with distillation capacity in the same way as to make sugar. However, the resulting cane juice is or sucrose-rich molasses are then fermented and then distilled to extract ethanol.

Major Sugar Producers and Consumers:

The top ten sugar producers in the world are: Brazil, India, Europe + UK, China, USA, Thailand, Mexico, Russia, Pakistan and Australia. Brazil and India are by far the largest sugar producers in the world and together produced a total of million 75.34 million tonnes in 2022/23. The top sugar consumers in the world are India, China, Indonesia, EU, USA, Brazil, Pakistan, Russia, and Mexico.