The Basics

PET resin (or Polyethylene Terephthalate) is one of the most commonly used thermoplastics. It plays an important role in everyday life and is used to make a wide range of packaging. It’s also the most recycled plastic globally and is easily recognizable by the symbol on most packaging types.

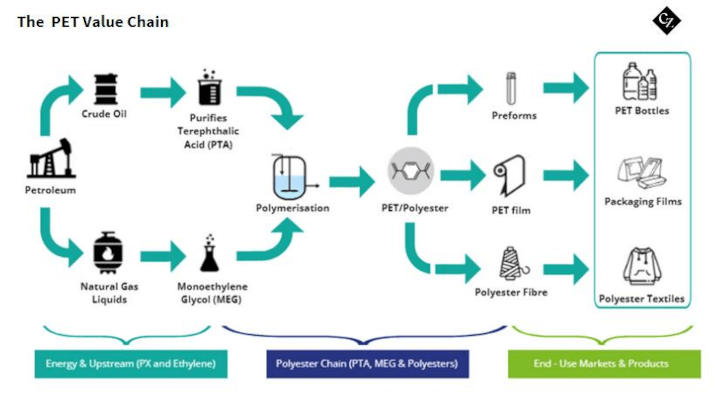

PET resin is produced through a polycondensation reaction using the feedstock monomers purified terephthalic acid (PTA) and monoethylene glycol (MEG).

The intermediate polyester polymer can be easily spun directly into fibres or extruded and cut into polyester chips, which can be traded and processed globally.

A higher Intrinsic Viscosity (IV) is required to produce Bottle Grade PET resin and uses a secondary process called Solid State Polymerisation or SSP.

Solid-stating and further crystallisation increases the strength and clarity of the final resin, and also reduces contaminants that would otherwise spoil the taste of drinks, such as bottled water.

The final resin can either be processed directly by beverage bottlers or moulded by third party converters into tubular preforms, which are blown into bottles at a different location.

Shatterproof: High tensile and impact strength means PET is flexible yet strong, making it shatter proof when dropped.

Easily Processed: PET resin can be easily moulded into different designs, making it ideal for distinct marketing and branding.

Lightweight: PET is extremely lightweight, reducing transportation costs and lowering carbon emissions.

Transparent: PET is highly transparent, making it easy to display and market certain food and beverages.

Highly Recyclable: PET is the most recycled plastic globally and can be easily recycled into similar applications as virgin resin.

Lower Carbon Footprint: When recycled correctly, PET bottles can have a lower carbon footprint than other packaging types.

End-Use Applications

In addition to the key properties described above, PET resin is also approved as safe for food contact by the FDA and other health agencies around the world, making it one of the most popular packaging materials in the food and beverage sector.

Beverage Bottles: Carbonated-soft drinks, water, sports drinks, juices, ready-to-drink tea and coffee

Food Bottles: Edible oils, milk and diary products, sauces, condiments, spreads, and other food stuff

Homecare: Cleaning and laundry products, detergents, hand sanitizer, and other hygiene products

Personal Care: Shampoo, soaps, facial cleanser, body wash, lotions, perfumes and cosmetics

Pharma Packaging: Blister packs, vials, bottles, and other containers

Thermoform Containers: Deli-containers, fresh produce trays, microwave and ovenable meal packaging

This Czapp Explainer was Published on the 7th June 2021.

For information on PET Resin and Plastic Packaging, please contact GLamb@czarnikow.com.